Broadcast Date:

- Time:

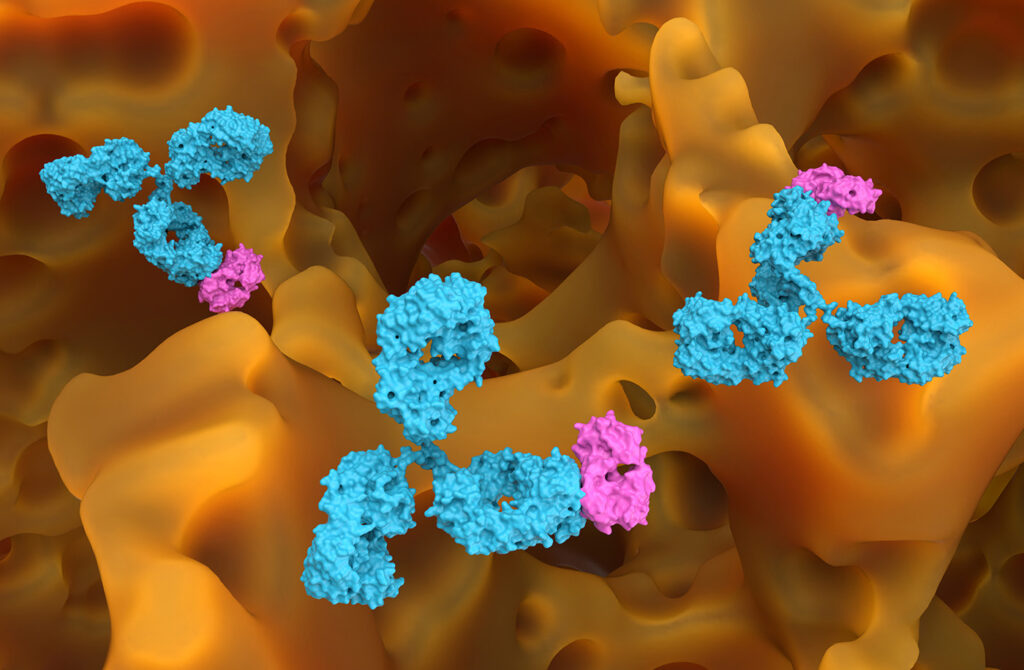

Technologies for manufacturing therapeutic monoclonal antibodies have matured in the decades since the first treatment was approved, but there are still workflow challenges that need to be addressed. Producing these biologics requires consistent and repeatable processes. However, a critical step—tangential flow filtration (TFF)—remains an important source of variability. Conventional TFF systems that rely on cassette holders and torque-based installation are prone to setup inconsistencies that can affect yield and reduce reproducibility. Newer designs address these issues, helping manufacturers work more efficiently and consistently.

In this GEN webinar, Mark Perreault will discuss strategies for improving mAb manufacturing using the latest technologies for separating, purifying, and concentrating therapeutic biomolecules. He will present case studies that illustrate a new flat-sheet holder-less TFF design for multi-use workflows along with data demonstrating the benefits of the design, including reduced operator errors and shorter setup time. You’ll also learn how the updated design removes the need for cassette holders and enables uniform flow distribution across the membrane surface while minimizing torquing and product loss.

Key takeaways include:

• How a holder-less design improves process reliability by eliminating installation issues and reducing operational complexity.

• How the design offers seamless scalability, as the device maintains consistent channel path lengths and pressure drop profiles across cassette formats.

• How uniform flow distribution enhances product yield and reduces variability in performance.

• How separation efficiency, flux rates, and fouling resistance of holder-less designs compare to traditional cassettes.

A live Q&A session will follow the presentations, offering you a chance to pose questions to our expert panelists.

Produced with support from: