In a groundbreaking development, a research team from Nagoya University in Japan has pioneered an innovative approach to X-ray beam manipulation by utilizing a single-crystal piezoelectric thin wafer of lithium niobate (LN). This revolutionary method enables the creation of a deformable mirror that can flexibly alter the size of X-ray beams by more than an astonishing factor of 3,400. This capability opens a wide array of possibilities in various industrial applications that rely on X-ray imaging and analysis.

Traditionally, the construction of mirrors for X-ray applications has relied on rigid two-part structures that are cumbersome and inherently resistant to deformation. These limitations present significant challenges when attempting to adapt to the shifting demands of real-time experiments, particularly in dynamic industrial settings. However, the innovative technique introduced by the Nagoya team transcends these obstacles, allowing for an unprecedented degree of control over X-ray beam size, thereby enhancing the analysis and imaging capabilities for users.

The essence of this breakthrough is the inherent piezoelectric nature of lithium niobate. This remarkable material possesses the ability to undergo changes in surface shape when subjected to an electric voltage, making it an ideal candidate for crafting mirrors that can be finely tuned to adjust X-ray beam dimensions. The researchers assert that the technique facilitates a dual-mode operation: users can first conduct a wide-field examination of a sample and subsequently focus on specific areas of interest with remarkable precision. This seamless transition drastically streamlines laboratory workflows, providing researchers with an efficient tool for sample analysis.

.adsslot_fH2tiuGX9Q{width:728px !important;height:90px !important;}

@media(max-width:1199px){ .adsslot_fH2tiuGX9Q{width:468px !important;height:60px !important;}

}

@media(max-width:767px){ .adsslot_fH2tiuGX9Q{width:320px !important;height:50px !important;}

}

ADVERTISEMENT

To actualize this state-of-the-art mirror, the Nagoya research team expertly harnessed the beneficial thermal properties of lithium niobate. Through the application of elevated temperatures within a specialized furnace, the researchers modified the polarization structure of LN. This polarization determines the extent to which the material can deform, ultimately leading to the development of a bimorph structure necessary for mirror functionality. Crucially, this innovation permits the creation of a single-crystal mirror, thereby bypassing the complications associated with chemical bonding found in traditional mirror designs.

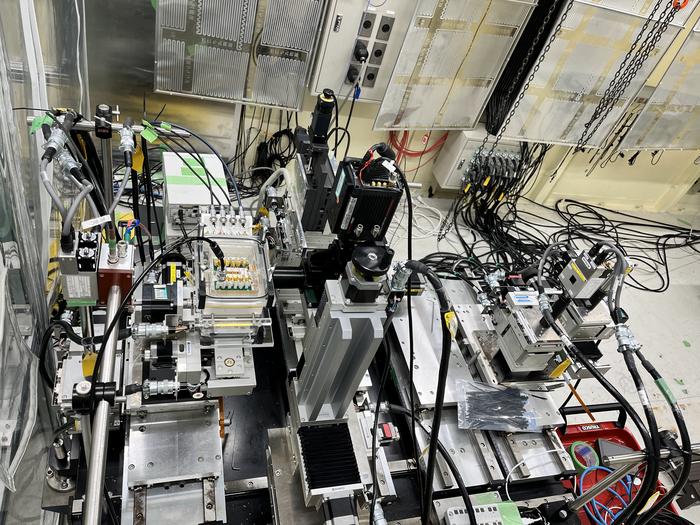

The dimensions of the newly developed mirror are astonishingly minimal, with a thickness reduced to a mere 0.5 mm. This feature not only enhances the mirror’s performance but also significantly increases its applicability across various fields utilizing synchrotron radiation in X-ray applications. The compact nature of the design further contributes to its versatility, as it can easily be integrated into various experimental setups without compromising space or usability.

Takato Inoue, a key figure in the research team and a member of the Graduate School of Engineering at Nagoya University, expresses optimism regarding the implications of this work. He anticipates that the advancements in mirror technology will substantially extend the possibilities for experiments that utilize synchrotron radiation in X-ray applications. The potential applications extend beyond just X-ray imaging; the mirror’s properties could also find utility in fields such as high-power laser experimentation commonly encountered in industrial environments.

The publication of this research in the esteemed journal Scientific Reports marks a significant milestone for the scientific community, illuminating the potential of piezoelectric materials in advanced X-ray applications. The work received funding through the Japan Science and Technology Agency’s Emergent Research Support Program, underscoring the importance of innovative research and development in the materials science sector.

As researchers look to utilize spectroscopy and diffraction methods more efficiently, this breakthrough in mirror technology is positioned to be a game changer. By fundamentally altering the way X-rays can be manipulated and observed, the implications for fields spanning materials science, engineering, and various industrial applications could be profound. Enhanced imaging capabilities will facilitate deeper insights into material structures, aiding in everything from basic research to the development of new materials.

This innovative mirror design may also bring about new methods for observing nanoscale properties in materials, pressing forward the boundaries of what is achievable with contemporary analysis techniques. By providing a robust tool for rapid adjustments in beam size, this technology allows for real-time analysis and observation of samples in ways that were previously unthinkable.

As the research community continues to explore the possibilities presented by this ultrathin monolithic bimorph mirror, the potential for collaborative advancements in materials physics, condensed matter physics, and crystallography grows exponentially. Other researchers are likely to build upon these findings, leading to further optimization of piezoelectric materials and devices.

The ongoing evolution of X-ray mirror technology not only benefits scientific exploration but also positions industries that rely on X-ray imaging at the forefront of advancement. The enhancements derived from these new methodologies could lead to more refined manufacturing processes, improved materials characterization, and superior quality control measures, showcasing how fundamental research can translate into practical applications that fuel progress across multiple sectors.

In conclusion, the singular achievement of creating a deformable mirror utilizing a single-crystal lithium niobate wafer is set to reshape expectations and standards in the realm of X-ray applications. As Takato Inoue and his team continue to forge ahead with this promising avenue of research, the future looks bright for both scientific inquiry and industrial innovation.

Subject of Research: Innovative X-ray beam manipulation using lithiuim niobate

Article Title: Ultrathin monolithic bimorph mirror using polarization-inverted lithium niobate wafer

News Publication Date: October 2023

Web References: Scientific Reports DOI

References: Takato Inoue et al. (2023), Scientific Reports

Image Credits: Takato Inoue

Keywords

X-ray diffraction, Solid state physics, Condensed matter physics, Piezoelectricity

Tags: crystal piezoelectric materialsdeformable mirror technologyenhanced imaging capabilitiesflexible X-ray mirrorsgroundbreaking X-ray techniquesindustrial applications of X-raysinnovative X-ray beam controllithium niobate piezoelectric waferNagoya University researchreal-time X-ray analysisX-ray beam manipulationX-ray imaging advancements