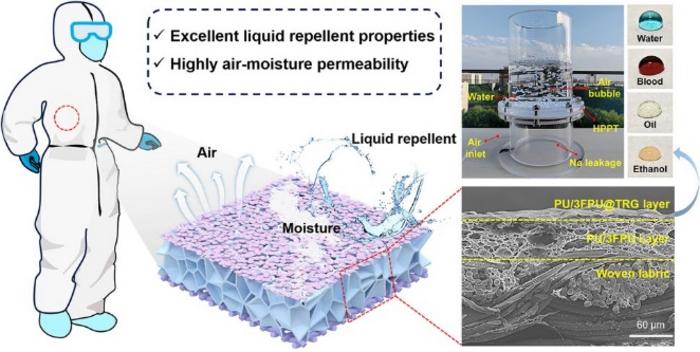

Researchers at Donghua University have made significant strides in the field of textiles, resulting in the creation of highly permeable and liquid-repellent textiles, referred to as highly permeable protective textiles (HPPT). This innovative advancement, documented in the reputable journal Nano-Micro Letters, addresses a critical need within the healthcare sector: the balance between effective protection and user comfort in medical wear. HPPT combines cutting-edge technologies to provide a viable solution for medical professionals and patients alike, marking a milestone in protective clothing.

The inspiration for this groundbreaking work stems from the inherent challenges associated with medical textiles. Traditionally, medical clothing often compromises comfort for protection, leading to discomfort for wearers during extended use. The research team, spearheaded by Professors Xianfeng Wang and Bin Ding, has recognized this disparity and set out to engineer textiles that would not only provide high levels of protection against fluids and contaminants but also ensure breathability and comfort. Their approach aligns with an ongoing trend towards improving healthcare workers’ attire as well as enhancing patients’ experience during treatment.

One of the hallmark features of the newly developed HPPT is its remarkable air-moisture permeability. The materials exhibit an airflow rate of 14.24 mm/s and moisture permeability of 7.92 kg m⁻² d⁻¹, a testament to their advanced design. These figures reflect a significant improvement over numerous commercial protective materials available in the market. The research indicates that, unlike conventional textiles which may retain moisture and heat, HPPT allows for continuous airflow while simultaneously repelling liquid substances, resulting in an optimal microenvironment for wearers.

.adsslot_5p4yWHXDAk{ width:728px !important; height:90px !important; }

@media (max-width:1199px) { .adsslot_5p4yWHXDAk{ width:468px !important; height:60px !important; } }

@media (max-width:767px) { .adsslot_5p4yWHXDAk{ width:320px !important; height:50px !important; } }

ADVERTISEMENT

The unique structure of HPPT is attributed to the integration of micro/nano-networks that were developed using an innovative non-solvent induced phase separation technique. The scientists employed a synergistic approach, utilizing calcium chloride and fluorinated polyurethane. This combination not only facilitates the creation of a resilient textile network but also enhances the water-repellent characteristics essential for medical garments. This strategic design ensures the production of textiles that are not just functional; they also embrace the latest industry standards for health and safety.

In the development of these textiles, meticulous attention has been directed toward the pore structure and overall textile architecture. The optimized micro/nano-network creates an average pore size of 1.03 µm and achieves a high porosity of 69%. Such specifications foster the necessary conditions for effective air flow while preventing liquid ingress. The direct benefits of this design are twofold: wearers enjoy comfort due to reduced moisture accumulation, and they are safeguarded from exposure to hazardous substances.

Molecular dynamics simulations and dynamic optical analyses were pivotal to validating the performance of HPPT. These advanced modeling techniques provide insight into the multi-stage phase separation mechanisms involved in the textile’s formation. The findings highlight the defining roles of calcium chloride and fluorinated polyurethane, which proved indispensable in regulating both pore formation and surface energy. By comprehensively understanding these underlying mechanisms, the research team is able to ensure the consistent reliability of HPPT across various environments and scenarios.

The implications of this research extend far beyond basic protective wear. The exceptional liquid repellency showcased by HPPT—demonstrated through its water contact angle (WCA) of 131°, blood contact angle (BCA) of 126°, and oil and ethanol contact angles reaching 104° and 85°, respectively—positions it as a formidable barrier against liquids even under dynamic conditions. Moreover, the mechanical strength of HPPT, which boasts a tensile strength of 65.56 MPa, outperforms materials such as high-density polyethylene (HDPE) membranes by a margin exceeding five times.

In addition to its protective features, HPPT exhibits impressive thermal and environmental stability, maintaining its functional integrity at temperatures extending to 50 °C. The textile’s formulation includes components that exhibit strong antibacterial properties, further enhancing its suitability for medical settings. These combined qualities both empower healthcare providers and engender an environment of safety for patients, effectively addressing health concerns associated with bacterial transmission.

Looking toward the future, researchers envision a multitude of applications for HPPT technology. Its potential doesn’t stop at medical apparel; it serves as an ideal candidate for the development of smart wearable electronics and bio-based antiviral fabrics. This versatility positions HPPT to play a vital role in various fields, ranging from outdoor performance wear to emergency response suits and industrial safety gear. With comfort, protection, and adaptability in mind, HPPT is set to redefine how textiles are utilized in critical environments.

The profound design and implementation of HPPT support a brighter outlook for medical professionals. Beyond their immediate applications, the materials represent a significant leap forward, enhancing both the safety and comfort of users who rely on such protective garments. The study conducted by Professors Wang and Ding also presents opportunities for industrial collaborations, leveraging existing manufacturing processes to bring this technology to market.

As Professors Wang and Ding continue to refine their research and explore various applications for their innovative textiles, the medical community and beyond eagerly await further developments. The potential for HPPT to transform protective textiles, thus improving the quality of care and safety in medical environments, speaks volumes about its relevance and importance.

This groundbreaking work is a testament to the power of interdisciplinary research, combining principles of engineering, material science, and biomedical technology. By pushing the envelope of what is possible in textile design, the research team is not only setting new benchmarks for protective clothing but also illuminating a path towards more advanced, functional, and life-saving materials in the healthcare industry.

As the research community anticipates further innovations in high-performance textiles, there is a shared understanding that protecting our health and enhancing our comfort are imperative goals. With HPPT at the forefront of this mission, we can look forward to a future where protection, comfort, and technology seamlessly converge.

Subject of Research: Highly Permeable and Liquid-Repellent Textiles

Article Title: Highly Permeable and Liquid-Repellent Textiles with Micro-Nano-Networks for Medical and Health Protection

News Publication Date: 9-Apr-2025

Web References: DOI Link

References: Nano-Micro Letters

Image Credits: Na Meng, Yuen Hu, Yufei Zhang, Ningbo Cheng, Yanyan Lin, Chengfeng Ding, Qingyu Chen, Shaoju Fu, Zhaoling Li, Xianfeng Wang, Jianyong Yu, Bin Ding.

Keywords

Nanomedicine, Bioengineering, Medical Technology, Health Protection, Advanced Textiles.

Tags: advanced medical textilesair-moisture permeability in textilesbreathable protective clothingcomfort in medical wearengineering breathable medical fabricshealthcare sector innovationshighly permeable protective textilesliquid-repellent textilesmicro and nano networks in textilespatient comfort during treatmentprotective clothing for healthcare workerstextile technology advancements