Optimizing the clarification of cell culture or fermentation broth is generally seen as a limited contributor to critical quality attributes (CQA). Researchers at Merck, however, say it’s time to rethink that assumption in light of higher cell densities, up- and downstream processing advances, and the increasing use of quality by design (QbD) principles.

Optimizing clarification processes via QbD principles “can improve control over process impurities and facilitate a logical quality control strategy, integrating quality in the process,” Merck scientists point out in a recent paper.

QbD has evolved from a risk management concept to meaning—as Jyotsana Balasaheb Jadhav, PhD, deputy general manager of R&D for Olon, wrote in 2014— “designing and developing manufacturing processes during the product development stage to consistently ensure a predefined quality at the end of the manufacturing process.”

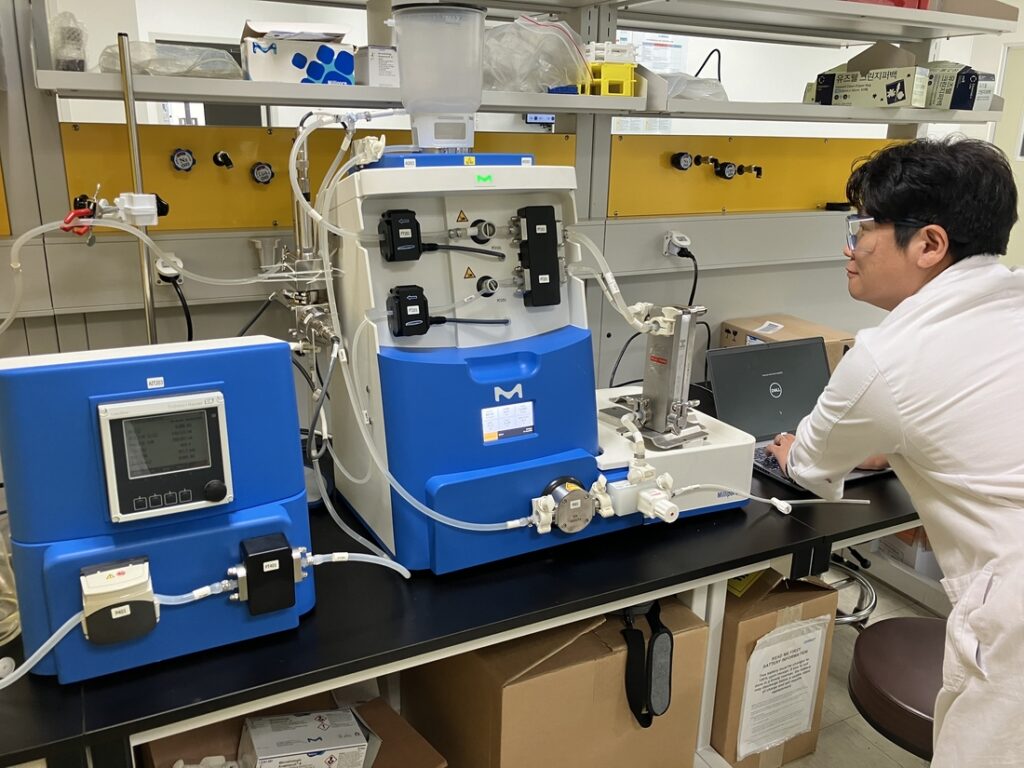

To that end, first author Kyeong-won (Kevin) Yeop, process development scientist, Merck, process solution, technical scientific solutions, DSP, MSAT, and a team of seven designed a harvest clarification process for an extracellular product.

Yeop and colleagues showed a leachables risk assessment model and then showed how that assessment changes. For example, shifting the clarification process from upstream to the purification step shifts “distance along production stream” from 1 (quite low) to 3 (just below moderate). When process fluid interaction, exposure temperature, and exposure duration are factored in, the leachable risk rating increases from 3.1 to 4.5 (moderate, but controllable).

They also showcase the cause-and-effect relationship between critical process parameters and CQAs. As they note, ions, glucose, amino acids, and other substances all contribute to the concentration of solutes that help maintain osmotic pressure in cells. Changes in osmolarity during the clarification process can enable cell lysis, which may affect the filtrate quality.

Flux, conductivity, and pH buffer conditions also may affect CQAs, they suggest.

Applying QbD to clarification

To improve product quality and reduce risks, they advocate applying QbD to the clarification process. As they note, defining a quality target product profile (QTPP) identifies CQAs and their parameters, thus removing impurities that may affect therapeutic efficacy. Aligning the QTPP with clarification helps manufacturers optimize processing parameters.

They then performed risk assessments to determine critical process parameters (such as centrifugation speed and buffer conditions) and CQAs. Then, they used design of experiment techniques to systematically optimize process parameters, thus tightening the relationship between process parameters and product quality.

Applying rigorous QbD standards to the clarification process enhances product safety and quality, as well as manufacturing reliability, they stress. By using this method, they say, “Biomanufacturers can enhance product quality, optimize processes, and ensure regulatory compliance throughout the product lifecycle.”