Panelists:

Matt Taylor

Senior Process Development Associate

KBI Biopharma

Panelist

Matt Taylor

Matt Taylor is a senior process development associate at KBI Biopharma, where he focuses on the design, optimization, and scale-up of purification processes for biopharmaceutical manufacturing. Matt joined the downstream process development department at KBI after earning his BS in chemical engineering from North Carolina State University. His work supports the development and commercialization of therapeutic proteins through the application of advanced chromatography and filtration technologies. Matt brings hands-on expertise in process characterization, technology transfer, and cGMP readiness, helping ensure robust and efficient downstream processes from lab to production scale.

Broadcast Date:

- Time:

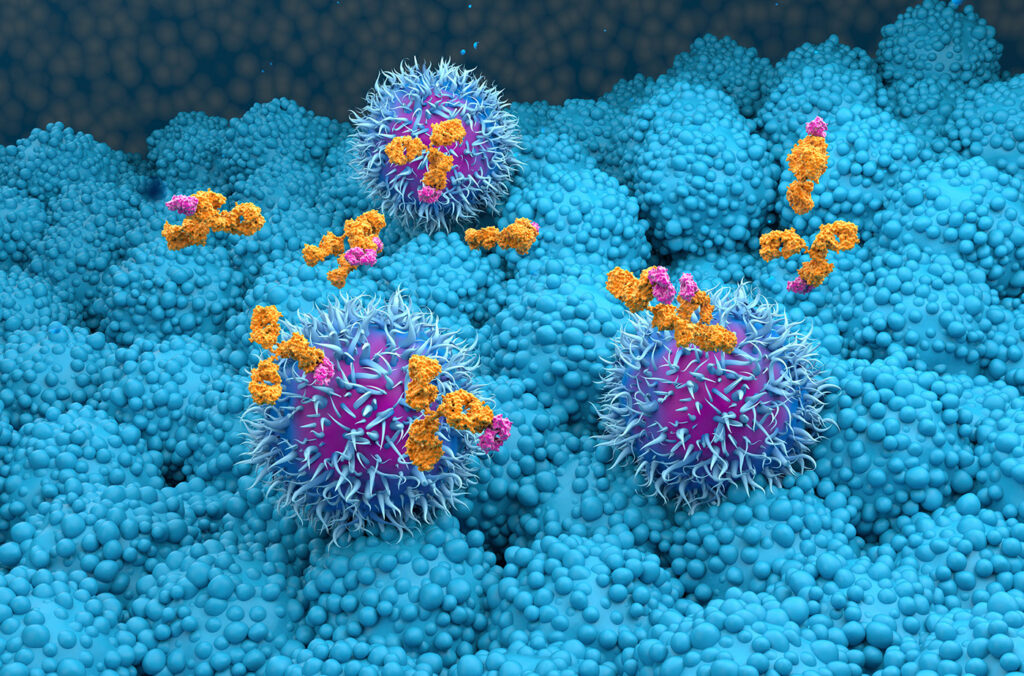

Process characterization and viral clearance validation are pivotal studies in biopharmaceutical manufacturing, particularly for monoclonal antibodies (mAb) produced in mammalian expression systems. As the demand for these therapeutics has grown in recent years, conventional column packing and validation methods have become a bottleneck for downstream manufacturing workflows. To stay competitive, manufacturers need agile validation methods that help them work more efficiently and shorten production timelines while meeting regulatory standards.

In this GEN webinar, our expert speaker, Matt Taylor, discusses how pre-packed chromatography columns can provide reliable small-scale models of the downstream mAb purification process. He will present data that demonstrates its performance equivalency to large-scale operations, offering an efficient alternative to traditional column packing. He will discuss how these pre-packed formats fit seamlessly into process development workflows and reduce preparation time, freeing teams to focus on value-added activities while adhering to ICH Q5A guidelines.

Key takeaways from the webinar:

- Feasibility of Pre-Packed Columns as Scaled-down Models: Understand how pre-packed chromatography columns can reliably model manufacturing-scale processes for mAb purification while aligning with ICH Q5A guidelines.

- Impact on Viral Clearance Validation: Learn how pre-packed columns deliver equivalent viral clearance performance, even with aged resin, while reducing preparation and experimental cycle times.

- Operational and Productivity Advantages: Explore how eliminating column packing and validation steps frees up development resources, accelerates timelines, and enables teams to focus on higher-value activities.

A live Q&A session will follow the presentation, offering you a chance to pose questions to our expert panelist.

Produced with support from: