In a groundbreaking study recently published in Scientific Reports, researchers V. Kumar, S.K. Yadav, and K. Vijetha delve into the intricate dynamics of two prominent welding techniques—Gas Metal Arc Welding (GMAW) and Shielded Metal Arc Welding (SMAW)—and their influence on the mechanical and microstructural attributes of E350 grade steel. This research is pivotal, given that E350 steel is frequently utilized in heavy structural applications due to its favorable strength-to-weight ratio and weldability. The authors present a comprehensive analysis that not only enhances our understanding of these welding processes but also aids in optimizing industrial applications.

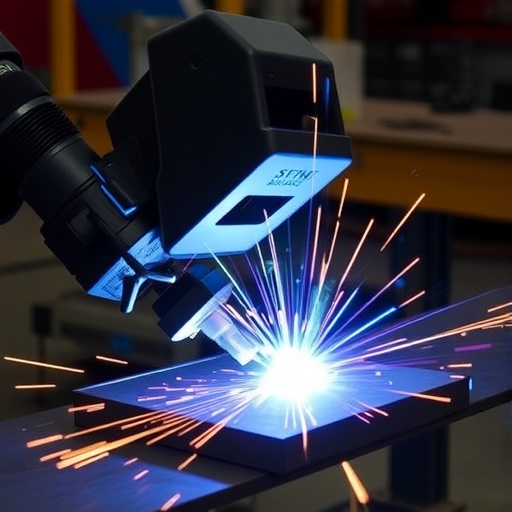

At the heart of this investigation lies the need to explore how different welding processes affect the integrity and performance of welded materials. GMAW, known for its adaptability and speed, offers a semi-automatic approach that results in smoother welds. Conversely, SMAW, often referred to as stick welding, is lauded for its versatility and ease of use, particularly in outdoor environments. The study sets out to compare these two methods systematically, utilizing E350 steel as a base material due to its widespread usage in industries such as construction and automotive engineering.

The researchers employed a meticulous experimental setup to conduct their investigations. They systematically engineered samples of E350 steel, subjected them to both GMAW and SMAW processes, and subsequently evaluated the resultant welded joints through a series of rigorous tests. The mechanical properties assessed included tensile strength, hardness, and impact resistance, each vital for applications where structural integrity is paramount. Additionally, microstructural examinations were conducted using advanced techniques like scanning electron microscopy (SEM) to visualize the phase transformations and grain structures resulting from the welding processes.

As the researchers delved deeper into their findings, they observed that GMAW presented distinct advantages in achieving enhanced tensile strength compared to SMAW. The higher cooling rates associated with GMAW resulted in finer microstructures, which are generally associated with improved mechanical properties. This was illustrated through tensile testing, where GMAW samples demonstrated superior bonding strength and ductility, a critical combination for structural applications. The intricacies of the molten welding pool and the gas-shielding environment in GMAW contribute significantly to these outcomes.

In contrast, while SMAW did exhibit lower tensile strength results, it surprised the researchers with its robustness in terms of impact resistance. The authors postulate that the slower cooling rates intrinsic to SMAW allow for a more gradual solidification process, thereby promoting tougher microstructural features. These characteristics make SMAW an appealing choice for applications where material toughness is prioritized, further underlining the importance of context in selecting welding methods.

Through meticulous microstructural analyses, the research team illustrated observed phenomena, revealing that the grain structure of GMAW specimens was markedly refined, with a greater proportion of fine-grained areas. In comparison, the SMAW specimens exhibited a coarser structure, which can be advantageous under specific loading conditions. The nuanced differences in the microstructure between the two methods underscore the need for welding process optimization tailored to application-specific requirements.

Another critical finding from the study highlights the role of impurities and their local clustering in the welded regions. Alongside mechanical testing, the authors employed energy-dispersive X-ray spectroscopy (EDX) to evaluate the elemental composition of the welds. They identified varying distributions of alloying elements, which substantially impacted the mechanical properties. Such detailed compositional analysis provided insights into how the welding techniques influence material performance, enhancing the overall understanding of weld quality.

Kumar and his team also emphasized the importance of parameter optimization in both welding techniques. The study explored how variations in welding speed, current, and voltage can significantly affect the resulting weld characteristics. For instance, they found that in GMAW, increased voltage resulted in a wider weld bead, which, when optimized, could lead to better fusion and less porosity. Meanwhile, adjusting parameters for SMAW revealed that fine-tuning the electrode travel speed could enhance penetration and bead shape.

Another layer of complexity was added by examining the post-weld heat treatment protocols on the welded joints. This aspect of the research aimed to analyze how processes such as annealing, quenching, and tempering could alter the mechanical properties of the welded E350 steel. The findings indicated that specific heat treatment regimes could significantly enhance hardness while simultaneously improving toughness, offering a promising avenue for future investigation.

The implications of these research findings extend well beyond academic interest; they resonate strongly within the manufacturing and engineering sectors. As industries continually seek to improve efficiency and performance, the insights gained from this study hold profound significance for selecting appropriate welding methods based on specific applications. Understanding the interplay between welding parameters and material response allows engineers and designers to create more reliable and robust structures.

Furthermore, the detailed characterizations afforded by this research contribute to a growing body of knowledge fostering innovations in welding technology. As engineers strive for sustainability, identifying the most effective and resource-friendly welding techniques is paramount. This work exemplifies the integration of materials science with engineering practices, providing a robust framework for future studies.

Additionally, as manufacturing processes evolve with digital technologies, this research underscores the importance of empirical data to guide the development of computer-aided systems for predicting weld performance. As artificial intelligence and machine learning begin to find their place in welding technology, foundational studies like this will be critical in training algorithms that anticipate the outcomes of various welding scenarios.

For practitioners in welding and structural engineering, the implications of this research are clear: a thorough comprehension of the strengths and weaknesses of different welding methods can profoundly influence design and fabrication choices. As industry standards evolve, embracing research-backed strategies will be crucial in achieving higher levels of safety, efficiency, and performance.

In summary, the comprehensive investigation presented by Kumar, Yadav, and Vijetha lays the groundwork for a deeper understanding of GMAW and SMAW processes and their significant impact on E350 steel. The researchers not only contribute valuable data but also inspire future innovations in welding technology against the backdrop of modern engineering challenges. As the industry continues to evolve, this pivotal research serves as a compass for engineers and researchers seeking to harness the full potential of welding methods in the pursuit of excellence and safety in design.

Subject of Research: The effects of Gas Metal Arc Welding (GMAW) and Shielded Metal Arc Welding (SMAW) on mechanical and microstructural properties of E350 grade steel.

Article Title: An investigation of the effect of GMAW and SMAW processes on mechanical and microstructural properties of welded E350 grade steel.

Article References:

Kumar, V., Yadav, S.K., Vijetha, K. et al. An investigation of the effect of GMAW and SMAW processes on mechanical and microstructural properties of welded E350 grade steel.

Sci Rep 15, 36338 (2025). https://doi.org/10.1038/s41598-025-20140-4

Image Credits: AI Generated

DOI: 10.1038/s41598-025-20140-4

Keywords: GMAW, SMAW, E350 steel, mechanical properties, microstructural properties, welding processes, tensile strength, hardness, impact resistance.

Tags: advantages of Gas Metal Arc Weldingadvantages of Shielded Metal Arc WeldingE350 steel propertiesGMAW welding techniquesimpact of welding on steelindustrial applications of E350 steelmechanical attributes of E350 steelmicrostructural analysis of E350 steelresearch on welding techniques and steel.SMAW welding techniquesstrength-to-weight ratio of E350 steelwelding process comparison