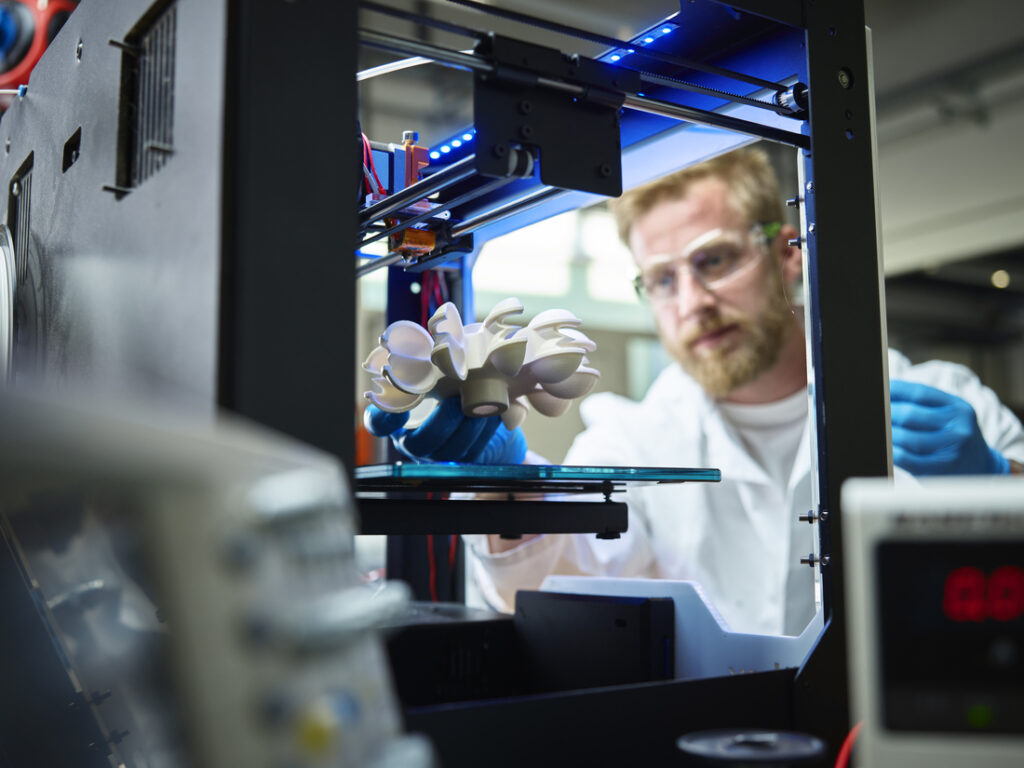

Bioreactor makers should consider using additive manufacturing, also known as 3D printing, according to a study, which suggests the potential benefits of the approach would be worth the investment.

Additive manufacturing involves the precise, sequential deposition of material to create solid forms. The main advantage is the ability to create complex three-dimensional objects that would be hard, if not impossible, to make using traditional techniques.

In biopharma, the approach is already used in a variety of ways: from drug production, with Aprecia’s modified-release antiepileptic Spritam (levetiracetam) being the obvious example, to the manufacture of mini-organs for drug toxicity testing.

More recently, bioprocessing tech firms have started to embrace it, according to Christophe Marquette, PhD, deputy director of the Institute of Molecular and Supramolecular Chemistry and Biochemistry at the University of Lyon in France.

“Bioreactors for cell and gene therapy manufacturing are currently produced as single-use devices using injection molding of mainly polycarbonate material. Their shape and functions are constrained by the molds. Additive manufacturing is an interesting option for bioreactors because it enables a freedom of shape but also size, without having to produce a new mold for every new design,” he tells GEN.

“In addition, it could also enable the production of bioreactors with exotic materials, including those that are conductive or biodegradable,” Marquette continues.

Cost versus flexibility

The challenge is that additive manufacturing is costly. Every operation is different, but, in general, an additive process is usually more expensive per part than an equivalent nonadditive process, making it less attractive for high-volume production.

However, for relatively low-volume products like bespoke, on-demand bioreactors, the potential benefits justify the investment, Marquette says.

“Additive manufacturing is always going to be more expensive than traditional methods that use injection molding, which have a high initial cost for the mold but a lower cost per part.

“However, for low-volume products like bioreactors, I think the flexibility of the approach outweighs the costs,” he says, adding that, “The sustainability characteristics are equivalent, assuming you use the same production materials.”

This take is in keeping with analysis Marquette and colleagues published recently.

“An interesting thing with additive manufacturing, and particularly in the study we did, is that relatively cheap printers can be used to make qualified bioreactors, which might be very useful for day-to-day research and for labs in low-income countries.”

The idea is also supported by investments seen in the technology sector, according to Marquette, who said, “Sartorius has a facility for additive manufacturing. Cytiva also has a facility in Sweden for the printing of bioreactor parts.”