In the relentless pursuit of miniaturization, modern electronics are rapidly shrinking towards the micrometer scale, enabling devices that can seamlessly integrate into human bodies, smart surfaces, and microrobots capable of wire-free motion. Yet, these technological marvels face a fundamental hurdle: how to power themselves without bulk and impractical energy sources? Conventional batteries, while reliable at macro scales, struggle to fit the design and functional requirements of microscale devices. Addressing this challenge, researchers from the Tata Institute of Fundamental Research (TIFR) in Hyderabad, India, in collaboration with University College London (UCL), have unveiled a groundbreaking planar micro zinc–air battery integrated directly onto microchips, achieving an unprecedented balance of power, size, and safety.

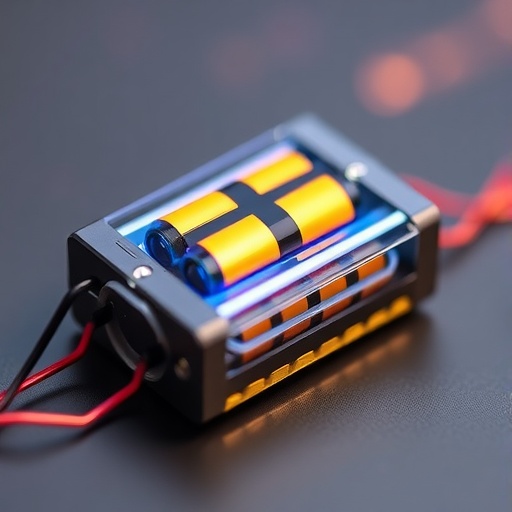

The novel zinc–air microbattery, coined CN-ZAMB, distinguishes itself by patterning both the anode and cathode electrodes in a single, flat plane on an interdigitated electrode (IDE) architecture. This design not only slims down the battery profile dramatically but also suits the exacting spatial constraints of integrated microelectronic devices. With electrode fingers as narrow as 200 micrometers, the battery adapts effortlessly to microchip surfaces, eliminating bulky stacks and enabling direct on-chip fabrication via precise electrodeposition and microplotter-assisted methods.

What makes zinc–air chemistry particularly enticing at the microscale is its use of ambient oxygen as one active reactant, mitigating the need for bulky, onboard chemical stores. Nevertheless, practicality has been elusive given existing approaches primarily rely on large, stacked configurations and aggressively alkaline electrolytes, which pose safety and compatibility concerns, especially in biomedical applications. Departing from these limitations, this research highlights the use of a near-neutral, gel-based electrolyte composed of ammonium chloride and zinc chloride, offering a safer, more compatible environment for microbattery operation.

The intricate electrochemistry at the core of the CN-ZAMB involves reversible zinc to zinc oxide conversion at the anode, complemented by bifunctional oxygen reduction and evolution reactions (ORR/OER) at the cathode. This is facilitated by the presence of electrolyte ions such as NH4+, Zn2+, Cl−, and water molecules, which orchestrate the electrochemical processes in a finely tuned equilibrium. The researchers’ meticulous electrodeposition technique enables the formation of cobalt/nickel catalysts on the cathode and zinc on the anode, optimizing both reaction kinetics and stability.

Scaling down to micrometer dimensions while maintaining robust electrochemical performance is no trivial task. The fabricated microbattery chip measures merely 2.25 cm by 0.75 cm with an active electrode area of just 1.15 cm by 0.6 cm. Yet, this compact footprint delivers reliable cycling, real current densities, and sufficient power output to illuminate LEDs and drive digital temperature and humidity sensors. Impressively, linking three such batteries in series powered an indoor-outdoor thermometer integrated with a hygrometer, showcasing practical utility beyond the laboratory.

This technological advance is a product of a synergistic two-institution collaboration leveraging distinct expertise. TIFR Hyderabad contributed its strengths in catalyst chemistry, materials science, and electrochemical characterization. Meanwhile, University College London provided cutting-edge capabilities in microfabrication, micro-plotting techniques, and device engineering. This fusion enabled precise control over material deposition, electrode design, and device integration—critical factors in viable microscale power sources.

Current challenges lie in the durability of the electrodes during prolonged cycling. Both anode zinc and cathode catalyst materials experience gradual degradation and loss, leading to diminished capacity over time. Researchers are actively investigating strategies to anchor catalytic materials more robustly onto electrodes, suppress dendritic zinc growth, and engineer enhanced bifunctional cathode catalysts. Achieving breakthroughs in these areas would pave the way for longer-lasting, higher-capacity microscale energy storage devices.

The implications of such advancements extend across multiple fields. With reliable on-chip microbatteries, wearable electronics can become completely wireless and autonomous. Internet-of-Things (IoT) sensor nodes can harness compact, safe power sources embedded directly into devices. Implantable medical sensors would benefit from biocompatible, stable energy supplies to monitor health metrics continuously without frequent battery replacements. Moreover, soft microrobots could gain unprecedented operational freedom through miniaturized onboard power.

This innovation is emblematic of the ongoing convergence between material science, microengineering, and electrochemistry, pushing the boundaries of what is possible at the micron scale. By integrating safe, near-neutral electrolyte chemistries with advanced microfabrication, the team demonstrates a paradigm where power sources no longer constrain device miniaturization but rather empower it. Such developments may drastically reshape how and where electronics operate, spawning entirely new classes of autonomous microdevices.

In sum, this first-of-its-kind planar micro zinc–air battery represents a major leap toward truly autonomous, chip-scale power solutions. While challenges remain in extending operational lifetime and performance, the foundational design—merging interdigitated electrode architectures, safe gel electrolytes, and high-performance catalysts—charts a clear path forward. The work underscores the transformative potential of microscale batteries for applications ranging from healthcare to environmental monitoring and robotics.

The collaborative research, published in the journal Small Methods, invites the scientific community to reimagine power delivery at the microscale and energizes the vision of integrating robust, safe, and highly efficient batteries directly onto chips. As research continues to refine materials and device configurations, the future of wearable, implantable, and adaptive electronics powered by these microscale zinc–air batteries looks both promising and revolutionary.

Subject of Research: Microscale Zinc–Air Batteries for On-Chip Powering of Miniaturized Devices

Article Title: Microscale Near-Neutral Zinc–Air Battery on Interdigitated Electrode Chips for High Current Operation

News Publication Date: 10-Nov-2025

Web References: https://doi.org/10.1002/smtd.202501562

References: S. R. Pattanayak, et al., “Microscale Near-Neutral Zinc–Air Battery on Interdigitated Electrode Chips for High Current Operation.” Small Methods, vol. 9, no. 12, 2025, e01562.

Image Credits: S. R. Pattanayak, et al.

Keywords

Microscale Battery, Zinc–Air Battery, Interdigitated Electrodes, Near-Neutral Electrolyte, Microfabrication, Electrochemical Energy Storage, Catalyst Optimization, Wearable Electronics, Implantable Sensors, Micro Robotics, On-Chip Power Sources

Tags: advanced battery materialsenergy efficiency in small devicesintegrated microelectronic deviceslightweight energy storage solutionsmicrorobots power sourcesmicroscale energy solutionsminiature battery technologyon-chip battery fabrication techniquesplanar micro battery architecturesustainable energy for microscale applicationsTata Institute of Fundamental Research innovationszinc-air microbattery design