Lightweight high-strength polymer composites have emerged as integral components in modern engineering, particularly given the increasing demand for advanced materials in aerospace, automotive, and various manufacturing sectors. Despite their importance, the manufacturing of these composites presents significant challenges. The conventional methods used in production are often complex and time-consuming, frequently reliant on manual adjustments that can introduce inconsistency and waste. This reality is set to change, however, as an innovative roadmap utilizing artificial intelligence (AI) has been proposed in a recent study published in the esteemed journal Frontiers of Chemical Science and Engineering.

This groundbreaking research, which is set to be published on December 5, 2025, outlines a transformative approach to the manufacturing of polymer composites. The international team of researchers behind this analysis aims to fully integrate AI within composite manufacturing systems, creating a setup that is not just automated but also self-optimizing. This change represents a critical shift from traditional methodologies that typically consider manufacturing steps as disjointed segments, instead advocating for a holistic view that enables the entire production chain to function cohesively.

The researchers argue that integrating AI into the design and manufacturing process can usher in an era of data-intelligent practices. Dr. Zijie Wu, a leading author from the Yaoshan Laboratory, emphasizes that this technology is not merely about task automation. Instead, AI facilitates a deeper understanding of the intricate relationships between material behavior, process parameters, and the final performance of composite products. This shift holds the potential for producing parts that are significantly lighter, stronger, and more reliable while simultaneously minimizing waste.

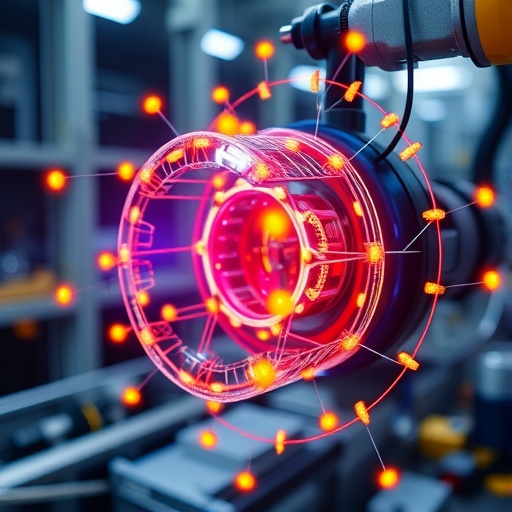

One of the primary innovations highlighted in the research is the application of physics-informed neural networks designed to model the curing stage of composite production. By harnessing historical sensor data, these advanced AI systems can predict the optimal heating and pressure conditions tailored for each part. The result is a reduction in production cycle times by as much as 30%, alongside a considerable decrease in energy consumption. Such advancements are pivotal for industries striving for efficiency and sustainability in their operational practices.

Another exciting innovation discussed in the study is the integration of hot pressing with injection molding, enabling both a structural base and intricate functional features to be formed in a single production run. Previously, achieving such complex geometries necessitated multiple separate processes that not only extended production timelines but also increased the risk of defects. By streamlining these operations through intelligent systems, manufacturers can not only enhance precision but also reduce overall production costs, making it an attractive option for businesses.

As the research delves into sustainability, its implications are profound. The current advantages of lightweight composites in reducing emissions during transport are amplified by making the manufacturing processes smarter and less resource-intensive. The advent of AI within this sector aligns well with ongoing global trends that prioritize environmental responsibility. Furthermore, this technology supports emerging concepts of “smart composites,” materials embedded with sensors or boasting self-healing capabilities—a reality made possible through more accurate and adaptable production methods.

The study represents a timely response to the pressing challenges faced by the composite materials industry, including the prohibitive costs associated with trial-and-error prototyping, inconsistencies in part quality, and the complications in scaling up new materials. Early adopters, including aerospace giants like Boeing and Airbus, are already testing similar AI-driven tools to enhance their autoclave processes and automated fiber placement techniques. Reports indicate that these companies have realized impressive efficiency gains, demonstrating the viability of AI integration in high-stakes manufacturing environments.

In conclusion, the research outlined in this study not only provides a robust framework for modernizing the manufacturing of polymer composites—bringing to light the incredible potential of AI in production—but also reinforces the crucial role that advanced materials will play in future industrial advancements. By harnessing the capabilities of AI for integrated process control, manufacturers can achieve higher product quality, operational agility, and contribute to a more sustainable industrial landscape.

As we anticipate this transformative technology to reshape the manufacturing processes, it paves the way for greater innovation within the composites industry, resulting in products that meet the evolving needs of society while adhering to stringent environmental guidelines.

Subject of Research: Not applicable

Article Title: Optimization and integration of polymer composites manufacturing powered by artificial intelligence

News Publication Date: 5-Dec-2025

Web References: 10.1007/s11705-026-2637-7

References: Not applicable

Image Credits: HIGHER EDUCATION PRESS

Keywords

Chemistry, Advanced Materials, Artificial Intelligence, Composite Manufacturing, Sustainability, Polymer Composites.

Tags: advanced material technologiesaerospace engineering innovationsAI in materials scienceautomotive manufacturing advancementschallenges in composite productiondata-intelligent manufacturing practicesfuture of engineering materialsholistic approach to manufacturinglightweight high-strength materialspolymer composite manufacturingprocess integration in productionself-optimizing manufacturing systems