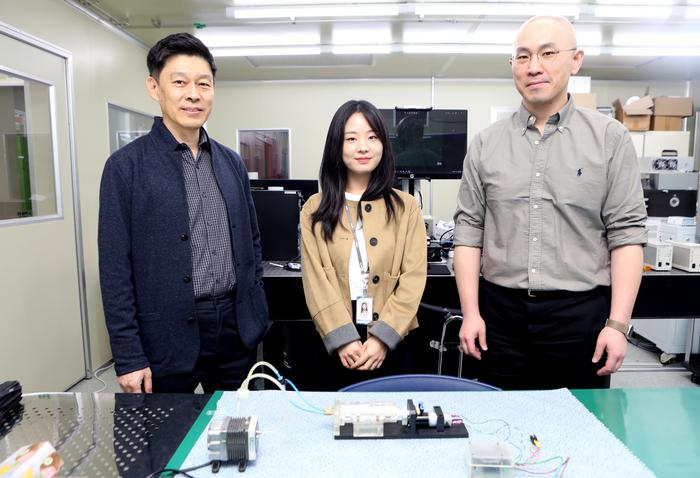

In a groundbreaking advancement for diagnostic technologies, researchers from the Korea Institute of Machinery and Materials (KIMM), led by Senior Researcher Kwanoh Kim, have introduced a revolutionary twin-screw-based mechanical pretreatment system. This innovative technology is designed to efficiently liquefy and homogenize solid biological samples in less than a minute, opening new avenues for rapid diagnostics that have previously posed significant challenges. The development of this compact device promises to transform the landscape of in vitro diagnostics (IVD), especially in situations requiring point-of-care (PoC) testing.

Traditional methods of preparing solid biological samples for analysis often involve lengthy processing times and cumbersome equipment. Conventional approaches rely heavily on complex machines that necessitate the expertise of trained laboratory personnel. This complexity makes on-site testing impractical in various settings, including emergency diagnostics and fieldwork. KIMM’s new device addresses these issues head-on, promising a swift, user-friendly solution that can be deployed almost anywhere.

The essence of the innovation lies in the twin-screw mechanism, which features counter-rotating screws that generate a high shear force, critical for the rapid liquefaction and homogenization of various solid materials. This mechanism sets the device apart from traditional methods, enabling it to break down tissue structures effectively and convert them into a uniform liquid state essential for many diagnostic applications. The compact design of the machine eliminates the need for additional bulky equipment, significantly enhancing its usability in diverse environments.

One of the standout features of this novel pretreatment system is its integrated internal fluid pathways. This advanced engineering minimizes sample loss during the process, ensuring high recovery rates of liquefied samples. In comparison to conventional methods, which often result in wasted samples due to inefficient processing, KIMM’s device provides a streamlined experience that prioritizes efficiency and accuracy. The research team has demonstrated that the system can be utilized for an array of sample types, including animal tissue, plant materials, and vegetables, showcasing its versatility.

Moreover, the system’s effectiveness extends to producing high-quality liquid specimens ready for immediate analysis. The rapid processing capability—completed in under one minute—could drastically enhance the speed of diagnostic evaluations, crucial in time-sensitive situations such as clinical emergencies or outbreak responses. With a focus on real-world applications, the mechanical device’s efficiency and portability are set to reshape the protocols in several fields, including agriculture, food safety, and environmental monitoring.

In addition to the powered device, the research team has also developed a portable, manually operated version of the pretreatment system. This variant ensures accessibility in locations where electricity may be unavailable, further enhancing the device’s applicability. The dual capabilities of powered and manual operation cater to a broader user base, making high-quality diagnostics feasible in remote or resource-limited settings.

Dr. Kwanoh Kim expressed optimism regarding the technological advances afforded by this device, stating that it establishes a foundational platform for solid-sample diagnostics. He emphasized that the twin-screw-based technology overcomes critical limitations faced by liquid-based IVD systems, which often struggle with the processing of solid samples. This innovation is expected to foster a wider range of diagnostic applications, enhancing both the flexibility and precision of analytical techniques.

The team at KIMM has taken significant steps to protect their intellectual property, filing six domestic patents related to their twin-screw pretreatment technology. Two of these patents have already been registered, solidifying core rights and paving the way for potential commercial applications. The expertise and innovative spirit displayed by KIMM have already garnered recognition in the scientific community, with their research being featured as a cover article in Analyst, a contemporary journal published by the Royal Society of Chemistry.

Aside from immediate applications in diagnostics, the implications of this technology are far-reaching. As sectors such as agriculture and food safety increasingly rely on rapid testing methods, KIMM’s device could become a vital tool in managing disease outbreaks and ensuring food safety. The potential for environmental monitoring is also significant—providing quick and accurate analysis of soil and water samples could enhance responses to environmental challenges.

This development is supported by the Ministry of Science and ICT through the Advanced GW Bio Project, which underscores the importance of government investment in future-oriented technologies. Such collaborations between research institutes and universities, like the partnership with Prof. Yoon-Joo Lee’s team at Sejong Chungnam National University Hospital, exemplify the synergistic approach required to tackle complex challenges in modern science and technology.

As healthcare systems continue to evolve in a fast-paced environment that demands rapid response times and high accuracy forecasts, innovations like KIMM’s mechanical pretreatment system will be indispensable. The integration of this technology into everyday diagnostic practices could set new standards for efficiency and reliability, driving advances in both clinical and field settings.

The research paves the way for new exploration in the domain of solid sample diagnostics, highlighting the critical importance of innovative solutions in an era where timely and precise diagnostics are imperative. As scientists and medical professionals continue to seek advancements that streamline workflows and reduce processing times, KIMM’s pioneering work stands at the forefront of this vital endeavor, promising to enhance not just medical diagnostics but public health as a whole.

In conclusion, this new twin-screw-based pretreatment system is a significant breakthrough in the field of diagnostics, combining speed, efficiency, and portability in a compact device. As its potential applications expand across various fields, KIMM’s innovation could revolutionize how we approach biological sample analysis, promising a future where diagnostic capabilities are both more accessible and effective.

Subject of Research: Twin-screw-based pretreatment technology for solid biological samples

Article Title: Portable and rapid solid sample preparation system utilizing twin-screw mechanism for diagnostic applications

News Publication Date: 7-Mar-2025

Web References: KIMM

References: Analyst, 2025, 150(8), 1523, DOI: 10.1039/D4AN01579G

Image Credits: Korea Institute of Machinery and Materials (KIMM)

Keywords

Diagnostics, twin-screw mechanism, pretreatment technology, biological samples, in vitro diagnostics, rapid testing, point-of-care testing, sample recovery, agricultural testing, food safety, environmental monitoring.

Tags: efficient liquefaction of biological samplesemergency diagnostics equipmentin vitro diagnostics innovationKIMM research advancementson-the-go diagnostics advancementspoint-of-care testing solutionsrapid diagnostic technologiessolid biosample processingsolid material homogenization techniquestransforming diagnostic landscapestwin-screw mechanical pretreatment systemuser-friendly laboratory devices