In the quest for cleaner and more sustainable energy sources, methane (CH₄) stands out as a widely available fuel with a high energy density. However, the practical storage and transportation of methane have long presented formidable challenges. Traditional approaches require storing methane as a compressed gas under extremely high pressures, near 25 MPa, or in liquefied form at cryogenic temperatures – conditions that are both energy-intensive and raise substantial safety concerns. Moreover, while adsorbed natural gas (ANG) technologies, which utilize nanoporous materials to store methane at moderate pressures (around 3.5 MPa), have attracted interest, these systems typically suffer from rapid loss of stored methane triggered by small temperature increases. This thermal sensitivity undermines the reliability and safety of storage, limiting ANG’s widespread adoption.

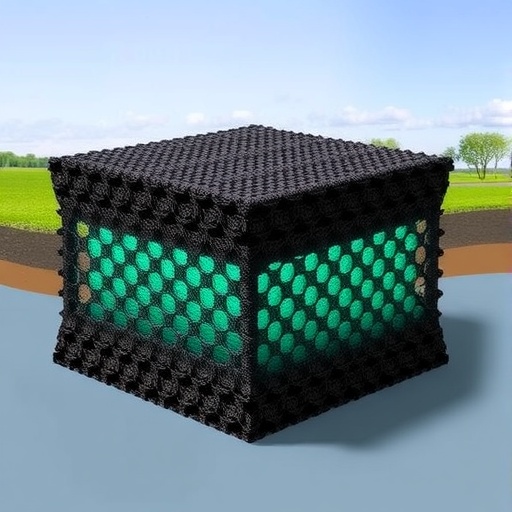

A groundbreaking advance now emerges from researchers led by Wang et al., who report a novel material system that fundamentally alters the paradigm of methane storage. Their work introduces graphene-coated porous carbon materials capable of storing methane at high density under high pressure and, crucially, retaining the gas at ambient pressure and moderate temperatures below 318 K. This method sidesteps the need for extreme compression during distribution and storage, offering a potent combination of safety, efficiency, and practicality. By functioning as a thermally responsive “lock,” the graphene coating controls access to the nanopores, permitting methane storage and release through temperature modulation rather than pressure adjustments.

The critical innovation lies in the use of graphene, a single-atom-thick lattice of carbon atoms renowned for unmatched strength, high thermal conductivity, and selective permeability. When coated onto porous carbon substrates, this graphene layer effectively gates the nanopores, dynamically obstructing or opening these channels in response to temperature changes. In doing so, it enables the trapping of methane molecules within the nanopores after a high-pressure charging phase, allowing the stored gas to remain locked at atmospheric pressure without leakage under standard conditions. The system can then be triggered by heating to approximately 473 K to release the methane on demand. This thermally mediated gating represents a fundamentally new control mechanism for gas storage materials.

Quantitatively, the graphene-coated porous carbon achieves a volumetric methane storage capacity equivalent to what would traditionally require pressurization near 19.9 MPa at room temperature (298 K). In practical terms, this capacity is reported as 142 volumes of methane per volume of storage material (v/v), a figure substantially surpassing the performance of existing adsorbed natural gas systems operating at much lower pressures. The material thus exhibits exceptional container space utilization, an essential metric for both vehicular fuel storage and large-scale energy infrastructure.

The implications of these findings extend beyond mere capacity improvements. By maintaining the stored methane at ambient pressure and moderate temperatures, the approach substantially enhances safety. High-pressure tanks inherently carry risk of rupture or leakage, while cryogenic liquid storage demands complex refrigeration and insulation. The graphene-coated porous carbon system minimizes such hazards, promising a new era of methane storage technology that aligns with stringent safety protocols for transport and distribution networks.

Beyond safety, the reversibility of the storage system stands out as a key advantage. The ability to lock methane in place at typical conditions and prompt its controlled release via moderate heating opens pathways for dynamic energy management and integration with renewable sources. For instance, methane could be stored efficiently during periods of surplus energy production and then retrieved on demand, smoothing supply fluctuations characteristic of wind or solar power.

Delving deeper into the material properties, the porous carbon substrate provides an extensive surface area and interconnected pore network, facilitating high methane adsorption capacity. The graphene coating, through its two-dimensional structure and exceptional mechanical properties, confers selective permeability and an effective thermal switch. Upon heating, thermal expansion and vibrational excitation disrupt the “lock” mechanism by modifying the graphene pore apertures, thereby enabling methane desorption. The interplay between graphene’s atomic-scale structure and the macroporous carbon scaffold underpins the material’s unique operational behavior.

Thermodynamically, the system counters the conventional challenge faced by adsorption technologies: the tendency for methane to desorb with even minor temperature increases at ambient pressure. The graphene “lock” mitigates this issue by physically constraining pore openings, enforcing kinetic stability under typical environmental fluctuations. This means methane remains securely contained during transport and handling without complex cooling or pressurization systems.

From an engineering perspective, such materials could revolutionize the design of natural gas vehicles and storage facilities. Reduced pressure requirements translate directly to lighter and less expensive storage tanks, enabling more compact and efficient fuel containers. This improvement not only cuts infrastructure costs but also enhances vehicle range and payload capacity. Environmental benefits arise from lowered risks of accidental methane release, a potent greenhouse gas contributor, thereby supporting climate goals.

The fundamental mechanism reported by Wang and colleagues expands the scientific understanding of how two-dimensional materials like graphene can be integrated to control molecular transport in porous solids. Their research cross-pollinates fields spanning surface chemistry, materials engineering and energy technology. It also sets a precedent for exploring other gas storage applications, including hydrogen or carbon dioxide capture, where similar controlled gating mechanisms could be transformative.

In addition to the performance metrics, the researchers likely engaged in sophisticated material characterization techniques to elucidate the structure and behavior of the graphene-coated porous carbon. Methods such as electron microscopy, Raman spectroscopy, and adsorption isotherm analysis would have been critical in confirming uniform graphene coatings, pore size distribution, and methane uptake/release dynamics. Understanding these factors enables precise tuning of storage conditions and optimization for specific application requirements.

Moreover, this study highlights the increasing potential for nanomaterials engineered at the atomic scale to solve longstanding industrial problems. Integrating graphene onto porous frameworks leverages synergistic effects: combining high surface area with structural sophistication to create stimuli-responsive materials. Such developments are instrumental in the transition toward cleaner energy vectors and smarter, safer fuel storage technologies.

Future research paths may include scaling up synthesis techniques for commercial production, improving thermal cycling durability, and testing performance under realistic operational environments. Addressing factors like cycling stability, cost-effectiveness, and integration with existing infrastructure will be crucial for translating laboratory innovation into commercial reality.

In conclusion, the reported graphene-coated porous carbon material represents a landmark advancement in methane storage technology. By enabling high-density methane retention at ambient pressure and temperature through a thermally activated graphene “lock,” the material overcomes key limitations of both conventional compressed natural gas and adsorbed natural gas methods. This breakthrough promises safer, more efficient methane storage solutions that could have far-reaching impacts on energy storage, distribution, and utilization, potentially reshaping the natural gas industry and advancing sustainable fuel technologies worldwide.

Subject of Research: Ambient pressure storage of high-density methane using graphene-coated nanoporous carbon materials.

Article Title: Ambient pressure storage of high-density methane in nanoporous carbon coated with graphene.

Article References:

Wang, S., Vallejos-Burgos, F., Furuse, A. et al. Ambient pressure storage of high-density methane in nanoporous carbon coated with graphene. Nat Energy (2025). https://doi.org/10.1038/s41560-025-01783-z

Image Credits: AI Generated

Tags: adsorbed natural gas technologiesambient methane storage solutionschallenges in methane transportationenergy-efficient methane storagegraphene-coated porous carbonhigh energy density fuelsinnovative materials for energymethane storage advancementsnanoporous carbon applicationssafe methane storage methodssustainable energy sourcesthermal sensitivity in gas storage