Sponsored content brought to you by

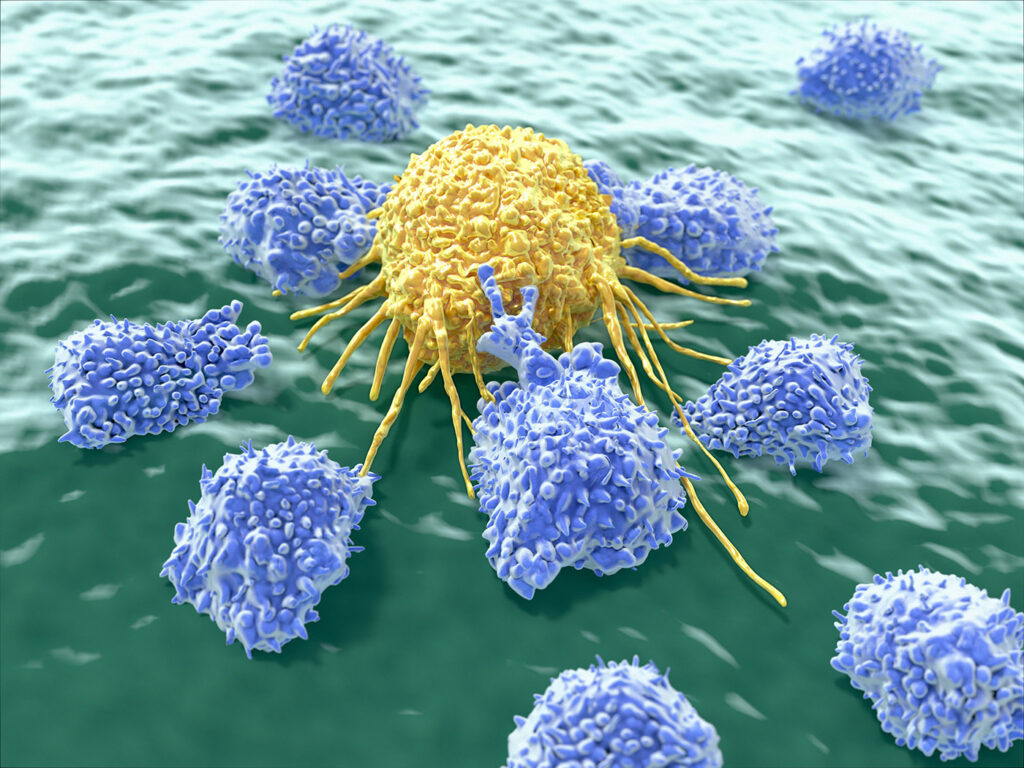

For decades, therapeutic monoclonal antibody (mAb) production relied on traditional batch-based manufacturing using stainless steel systems. But as biopharmaceutical pipelines grow to meet rising demand for these important biologics, downstream processing must evolve to support faster, more scalable production. In response, many companies are rapidly adopting technologies that improve consistency, reduce contamination risks, and accelerate the time to market for new biologics.

This urgency is reshaping how scientists approach tangential flow filtration (TFF), a crucial downstream step in the concentration and purification of mAbs and other biologics including antibody-drug conjugates and viral vectors. While traditional stainless-steel TFF systems are durable and modular, they rely on traditional cassettes and holders that require precise torquing and complex multi-step assembly, which risks inconsistent sealing, operator error, and increases potential product loss or contamination during repeated use or scale up. Overcoming these operational challenges is the focal point for innovations in TFF system design.

Innovation in response to biomanufacturing pressures

Single-use TFF devices are an attractive option for manufacturers seeking solutions that eliminate setup complexity, reduce contamination risk, and streamline workflows. Meanwhile, multi-use TFF devices are evolving to meet mAb’s manufacturers’ need for efficiency, consistency, and reduced operational burden. While traditional stainless-steel cassette-and-holder assemblies offer durability, they introduce complexity around setup, torquing, and cleaning validation. More recently, the industry has shifted toward the next-generation of multi-use, holder-less TFF designs: self-contained, flat-sheet cassettes that combine the performance of conventional systems with streamlined handling and validated cleaning protocols.

One such example is TangenX® SC, a next-generation TFF cassette device from

Repligen for processing mAbs and other biologics. The device’s holder-less sealed design, where the membrane, flow channels, and housing are integrated into a single, sealed unit, significantly improves ease of use, performance consistency, and mitigates risk.

Unlike legacy TFF devices, TangenX SC is factory-assembled, pre-sterilized, and validated for uniform pressure distribution resulting in an 80% reduction in process setup as well as reduced decommission time and operator risk. Because TangenX SC’s plug-and-play format does not require special hardware or tools, scientists and process engineers can transition quickly between clinical and commercial-scale production. The cassette leverages Repligen’s ProStream and HyStream membranes, with the option of five different molecular weight cutoffs. Importantly, TangenX SC was designed with cross-scalability in mind. It uses the same high-performance membranes, similar surface area options, and flow path geometries as legacy cassettes allowing developers to move seamlessly from older designs to SC without reworking core process parameters.

Repeated use, high recovery across multiple cycles

Performance data on TangenX SC show that it is comparable to traditional cassettes in terms of product recovery, membrane integrity, and process consistency. For multi-use applications, it offers consistent output across batches. Internal tests have shown that the device maintains performance over as many as 20 cleaning cycles under controlled conditions (see Figure 1). However, the validated recommendation for multi-use campaigns is up to 10 reuse cycles, based on standard cleaning protocols and routine process conditions. This conservative threshold balances operational efficiency with regulatory

expectations for reproducibility and batch-to-batch consistency.

Designed for the future of mAbs manufacturing

The pivot toward closed and continuous systems is accelerating as biopharma companies aim for higher product quality from scalable processes. In an environment where reducing instances of manual handling, open processing, or equipment changeover are essential, adopting TangenX SC can mean the difference between meeting product milestones or missing them. For scientists and process engineers, it means greater control, agility, and productivity in pursuit of therapies that reach patients faster and with higher quality assurance.

Researchers can learn more about the TangenX SC and other devices at: www.repligen.com.