As RNA therapeutics evolve far beyond their vaccine origins, a new generation of scientists and manufacturers is rethinking how to produce these complex medicines safely, efficiently, and at scale. From template design and enzymatic capping to lipid nanoparticle (LNP) formulation and purification, the challenges extend across every stage of development. Four industry leaders—CordenPharma, GENEWIZ, Lonza, and New England Biolabs—are advancing the technologies, analytical methods, and supply chains needed to meet these demands. Together, their work reflects a shared mission: to turn RNA’s extraordinary biological potential into reliable and reproducible therapies for a wide range of diseases.

As RNA moves from the narrow world of pandemic vaccines into the broader therapeutic landscape, scientists are rethinking how to scale production for an entirely new class of medicines. “We’re not just scaling up—we’re scaling out,” says Nicole Nichols, PhD, executive director of applications and product development at New England Biolabs (NEB). This shift reflects a future in which RNA-based treatments are tailored to individual patients, requiring flexible, modular, and efficient manufacturing strategies capable of handling smaller, more customized production runs.

According to Nichols, the nature of each RNA therapeutic “will likely dictate how it is designed.” For instance, transient genome-editing therapeutics may rely on short-lived RNA, whereas protein-replacement therapies demand molecules with extended durability and controlled half-lives. The rapid development of new modalities—particularly self-amplifying RNA (saRNA) and circular RNA (circRNA)—is expanding the RNA therapeutic toolbox. Each of these formats has distinct stability, expression, scalability, and reagent needs, all of which must be factored into process design and regulatory compliance.

Getting beyond bottlenecks

Nichols identifies two major bottlenecks that currently limit scalability. The first involves template generation, a crucial upstream step traditionally dependent on plasmid-based systems. These methods produce the desired results, but they are slow and resource-intensive. “Alternative approaches based on PCR and isothermal amplification,” she explains, “offer flexibility and speed for the next generation of RNA therapeutics.” Cell-free template generation systems are also emerging as promising solutions, enabling rapid prototyping while maintaining high fidelity. To improve the generation of templates, NEB developed a GMP-grade Q5 Hot Start Polymerase, which provides high-fidelity template amplification that minimizes mutation risk.

The second bottleneck is the mRNA capping process, which directly impacts translation efficiency and RNA stability. Chemical cap analogs provide convenience but are costly and inefficient, as only a fraction of the analog is incorporated. Enzymatic capping offers superior efficiency but typically requires an independent capping reaction. For example, NEB developed a fusion enzyme that links a single-subunit capping enzyme with T7 RNA polymerase, enabling co-transcriptional enzymatic capping using low-cost GTP and saRNA—simplifying workflows and enhancing yield.

Looking forward, Nichols anticipates a future in which “RNA can be engineered the way we’re currently able to engineer DNA.” Advances in RNA QC and immune repertoire sequencing, together with continuous flow manufacturing and enzyme reuse, are poised to drive personalized, scalable, and economically viable RNA therapeutics that could transform healthcare globally.

Expanding the reach

As RNA-based therapeutics gain momentum across the biotechnology landscape, researchers and manufacturers are exploring how to design, stabilize, and produce these complex molecules at scale. GENEWIZ—a global provider of genomic and synthetic biology solutions that is now part of Azenta Life Sciences—is helping to shape the technologies and workflows that bring RNA concepts from the laboratory to clinical reality, according to Andrea O’Hara, PhD, senior product manager for integrated solutions, multiomics and synthesis solutions.

“RNA therapeutics encompass a wide range of clinical applications,” O’Hara explains. These include antisense oligonucleotides (ASOs) and small interfering RNAs (siRNAs), which can silence or modulate gene expression to address inherited and acquired diseases such as spinal muscular atrophy and Duchenne muscular dystrophy. At GENEWIZ, her team supports “the full research and development pipeline” for RNA therapeutics—covering upstream design and synthesis of ASO, siRNA, mRNA, and circRNA constructs, as well as downstream quality control of the final product. “Importantly, we also support analysis of the cells and organisms pre- and post-treatment to confirm expression, safety, and efficacy of the therapy itself,” she adds.

O’Hara identifies two persistent challenges in RNA therapeutic development: molecular stability and delivery. “One primary concern is stability of the RNA molecule,” she notes. “To aid in stability, there are a variety of different modifications that can be used, in conjunction with the type of RNA therapy selected.” These chemical or structural modifications are often tailored to the specific mechanism of action—whether transient gene silencing or sustained protein expression. Delivery is equally crucial, influencing how efficiently and safely RNA reaches its cellular target. “There is no one-size-fits-all approach,” O’Hara emphasizes. “Thoughtful design and consultation are critical, as is routine QC throughout development to ensure the product is safe and pure.”

To address these challenges, GENEWIZ applies a “rigorous QC process at each step,” using a suite of analytical tools to ensure precision and reproducibility. Plasmids are verified by Sanger or whole-plasmid sequencing to confirm clonal integrity. The final mRNA product undergoes extensive testing: LC-MS assays for poly(A) tail length and capping efficiency, double-stranded RNA (dsRNA) residue analysis by ELISA, RNA length and purity by gel electrophoresis, and residue assays for proteins, plasmid DNA, and endotoxins. Next-generation sequencing is then used to validate the transcript sequence and confirm accuracy.

Through this combination of innovation, analytical rigor, and scientific collaboration, O’Hara and her team are helping scientists push RNA therapeutics beyond the boundaries of research—toward safe, scalable, and transformative medicines that may help redefine the future of genetic healthcare.

Scaling precision in manufacturing

For Torsten Schmidt, head of operations for specialized modalities at Lonza, advancing RNA therapeutics manufacturing is not just about scaling up—it’s about mastering complexity and precision. As one of the world’s leading contract development and manufacturing organizations (CDMOs), headquartered in Basel, Switzerland, with more than 30 sites worldwide, Lonza plays a central role in helping biotech and pharmaceutical companies transform RNA-based discoveries into clinical and commercial reality.

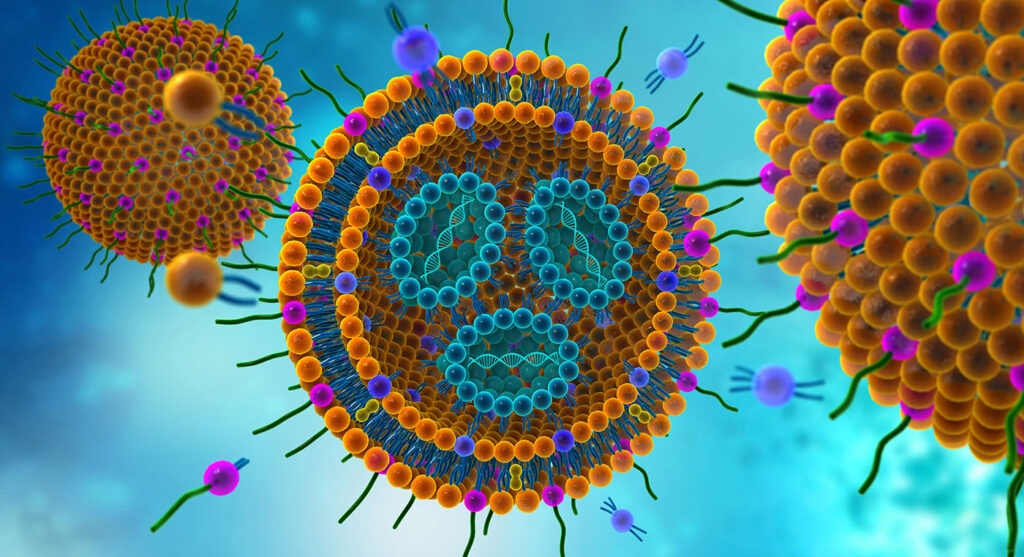

“At Lonza, we develop process platforms which enable scale-up from bench research to commercial production,” Schmidt explains. The company’s integrated approach covers every phase of the mRNA manufacturing process—from DNA template supply and in vitro transcription (IVT) to capping, purification, LNP formulation, and aseptic filling. “In addition to scalability, we prioritize establishing a robust supply chain for specialty lipids and enzymes by collaborating with qualified suppliers,” he adds. Lonza is also investing heavily in next-generation analytical technologies and refining process-development capabilities to master increasingly complex targeted LNP systems.

Manufacturing RNA therapeutics, Schmidt emphasizes, requires far more advanced capabilities than traditional vaccine production. “Beyond manufacturing constraints, challenges in the regulatory process include on-target/off-target activity and residual impurities,” he says. Designing RNA with high precision is crucial for achieving the intended therapeutic effect while avoiding unwanted biological responses. During IVT, removing residual contaminants, such as dsRNA, is especially important, since these impurities can trigger immune activation and reduce therapeutic efficacy.

To meet these challenges, Lonza draws on its deep expertise in bioconjugation and purification. “We are addressing challenges in manufacturing RNA therapeutics in a few ways,” Schmidt explains. “This includes the conjugation of protein moieties to LNPs and the removal of dsRNA as an impurity.” For LNP conjugation, the company uses covalent linking through maleimide groups and cysteine-engineered proteins—a process that demands careful study of LNP stability, immunogenicity, and analytical characterization. Because RNA therapeutics often require doses roughly 1,000 times higher than vaccines, purification becomes a key determinant of safety, efficacy, and regulatory compliance.

Looking ahead, Schmidt anticipates transformative breakthroughs in in vivo gene editing and CAR T therapies driven by mRNA-loaded LNPs. “In vivo CAR T therapy using LNPs is a transformative advancement,” he says. “It allows CAR T cells to be generated directly in the patient’s body, making treatment faster, safer, and more accessible.” For Schmidt, such innovations signal the next evolution in RNA therapeutics—where scalable manufacturing, precision design, and patient accessibility finally converge.

Integrating lipids in RNA therapies

At CordenPharma, a global CDMO headquartered in Basel, Switzerland, scientists are expanding the frontiers of RNA-therapeutics manufacturing by refining the chemistry and engineering of LNPs to deliver RNA-based medicines. For this company’s Jason Coleman, PhD, associate platform director for lipids & LNPs, and Serra Gürcan, PhD, associate platform director for lipids & LNPs, the goal is to help clients translate scientific innovation into scalable, high-quality production.

“In many ways, the manufacturing process itself is similar across applications,” Coleman explains. “The differences arise from the components in the formulation and how those components interact with the specific therapeutic application.” Both he and Gürcan bring deep experience in nanoparticle drug delivery, supporting customers through formulation, process development, and scale-up. “Our role today is to provide insight from the lipid-manufacturing standpoint—how to produce highly pure lipids, what to avoid, and how to maintain consistent quality across scales,” Gürcan says.

CordenPharma’s expertise spans both the LNP process and the lipid inputs that define performance. The company supplies catalog lipids but also works closely with clients, developing novel, custom-designed lipids. As RNA therapeutics move beyond vaccines, these formulations are becoming more sophisticated. “LNPs are inherently complex,” Gürcan notes. “Now, with extra-hepatic delivery and conjugated LNPs, we’re adding more layers of complexity.” Beyond manufacturing, biological challenges persist—ensuring RNA escapes the cytosol, avoiding immunogenicity, and managing repeated dosing. Polyethylene glycol (PEG), for example, long used in the pharmaceutical industry to stabilize nanoparticles, has raised concerns. “Repeated dosing can reduce potency because the body begins to recognize PEG,” Gürcan explains. Coleman adds, “There’s a lot of work going on to develop PEG derivatives or find alternatives that avoid immune responses.”

Manufacturing conjugated or targeted LNPs introduces additional challenges. “Finding CDMOs that can produce conjugated LNPs at GMP scale is difficult,” Coleman says. To address this, CordenPharma is developing new conjugated lipids designed specifically for LNP chemistry and investing in expertise to perform bioconjugation at scale. The company also uses plant-based cholesterol derivatives that are less immunogenic and can increase RNA expression by up to 45%.

“Our innovation teams are focused on developing alternatives to PEG and expanding beyond mRNA to plasmid DNA and CRISPR-based payloads,” Gürcan says. Coleman adds that cost and consistency remain industry-wide priorities: “The real challenge isn’t just in manufacturing—it’s in improving delivery and doing it in a repeatable, reproducible, and affordable way. We’re not there yet, but we’re getting closer.”

Toward a new RNA era

Across the RNA-therapeutics landscape, progress depends on more than scientific insight—it demands collaboration across every link of the manufacturing chain. From high-fidelity enzymes and advanced quality control to novel lipids and large-scale production, companies like CordenPharma, GENEWIZ, Lonza, and New England Biolabs are laying the technical and logistical groundwork for the next wave of RNA-based medicines. Their collective efforts point toward a future where precision-engineered RNA therapies can be delivered safely, affordably, and globally—transforming not only how diseases are treated, but how modern biotechnology redefines the possibilities of medicine itself.