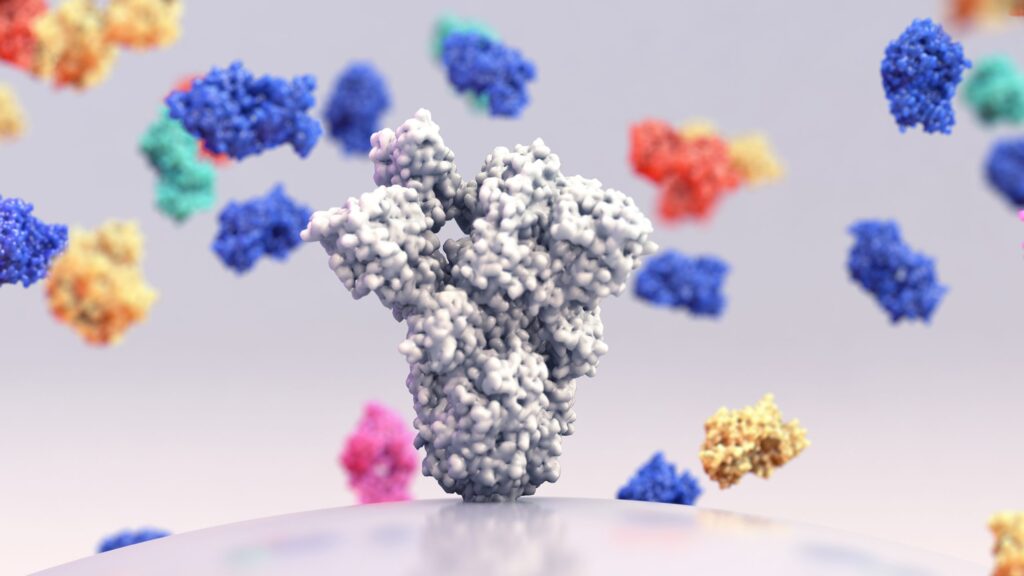

Credit: Design Cells/Getty Images

Monoclonal antibodies (mAbs) make up one of the most important classes of advanced biotherapies. To find out about the current challenges and advances in the production of mAbs, GEN talked with Lukas Bialkowski, PhD, market development manager, bioprocessing at Beckman Coulter Life Sciences, and Gregor Kalinowski, PhD, senior principal scientist at Cytiva.

GEN: What are the most important challenges in producing therapeutic mAbs?

Bialkowski: Because mAbs are produced by cells, scientists must screen thousands of clones that have similar specificity against the desired target but that differ in quality and their ability to efficiently produce large amounts of protein. Researchers typically select clones in three stages, starting from thousands of clones, then moving to hundreds, and finally to a group of about 10 from which they will make their final selection. Moving from the second to the third stage has traditionally been challenging because cells behave differently depending on the culture volume, so when researchers change volumes in cell culture, they might end up with clones that produce lower quantities of mAbs than they normally would. The risk is that they’ll end up picking the clone that’s not the most optimal choice for the manufacturing conditions.

Another challenge is measuring and maintaining critical quality attributes, or CQAs, which are properties of mAbs that must stay within appropriate limits or ranges to ensure safety and efficacy. A particularly challenging CQA is aggregation, the process by which proteins stick to each other, which negatively impacts efficacy. When proteins clump together, they can mask key structures that help the mAbs find their antigen targets. Developers must screen for aggregates so they can select antibodies that meet a certain threshold of aggregation, for example, aggregation below five percent can be one of the CQAs.

Kalinowski: Generally speaking, we are always working with our customers to accelerate production while working to reduce costs. There aren’t any real technical challenges for standard mAb concentrations up to 150 g/L. However, with high-concentration mAbs, the viscosity increases exponentially. This impairs product recovery from the processing system, resulting in poor yields at target concentrations of above 200 g/L. Additionally, sheer stress could also be another limitation for high-concentration mAbs. One way to address this is to make sure you have appropriate filters and technology in place.

GEN: How are recent advances in cell selection helping address these challenges?

Bialkowski: Optimizing clone selection enables scientists to screen more clones in less time and increases the chances they’ll pick the right one. There are now instruments designed to improve screening at that second stage, during which researchers are working with 100 or more clones. Traditionally, researchers were stuck in a lab, feeding those cells, checking on them, and measuring many different parameters every day for about two weeks. With new technology, researchers can now test up to 96 clones simultaneously, adjusting the global set points for pH and dissolved oxygen, while at the same time providing cell viability and titer measurements in a fully automated manner.

Screening for CQAs, such as aggregation during cell selection, is also important. This process typically starts in the late stages of process development, after researchers have already narrowed down their pool of clone candidates. Now, with improvements in cell-selection technologies, it’s becoming easier to screen for aggregates at an earlier stage of the development process, which could help developers select the clones that are most likely to maintain a low level of aggregation. This ultimately could reduce mAb-development timelines.

What’s more, high-throughput, plate-based screening assays are enabling more efficient and precise characterization of cells. For example, it’s now possible to measure aggregation in 96 samples simultaneously using plate-based fluorescent polarization assays. Each well of the plate can be coated with a fluorescent small molecule that binds to protein aggregates. Then the technology excites the fluorescent molecule with polarized light and measures changes in rotational speed. The degree of rotation of the molecules will differ depending on their size: Big, aggregated molecules rotate slowly. The quicker the rotation, the less aggregation. The technology can rank the samples on each plate from the lowest to the highest levels of aggregation, making it easy for researchers to spot their most stable clones.

GEN: How much faster can suitable cells be selected with today’s methods compared to, say, five years ago?

Bialkowski: With many steps of clone selection now being automated, our study has shown researchers can save up to 90% of the time it takes to screen clones.

When it comes to measuring aggregation, plate-based aggregation studies reduce the need for instrumentation, columns, and multi-step workflows that are required with traditional methods such as dynamic light scattering (DLS) and high-performance liquid chromatography size exclusion chromatography (HPLC-SEC) technologies. It’s now possible to measure 96 samples in as little as 15 minutes. By comparison, DLS takes one to two hours, and HPLC-SEC can take more than six hours.

GEN: In the near future, what additional improvements will be most important in producing therapeutic monoclonal antibodies and why?

Kalinowski: Improving efficiencies in process intensification for both traditional mAbs and high-concentration mAbs will help reduce costs. Additionally, for high-concentration mAbs, efficient buffer-system optimization is essential to reduce viscosity and stabilize the product.

Bialkowski: Companies are working on adding automation to workflows, which will enhance cell selection by preventing errors from manual pipetting and further reducing the time needed to set up and run the assays. For example, the ability to automate the fluorescent-light polarization measurements, without manual intervention, would improve aggregation testing.

We also need to perfect these instruments for more complex antibody development. That’s because there’s an increasing focus not just on mAbs, but also on antibody therapies that can attack more than one target simultaneously. They include bispecific antibodies in cancer, which contain regions that recognize both tumor targets and immune cells, or, alternatively, block two separate pathways simultaneously. This type of precision medicine is the future, and enhancing cell selection will enable that.