In an era where efficient and compact microwave components are indispensable for advancing communication technologies, a groundbreaking study has emerged that promises to revolutionize the design and fabrication of microwave power splitters. Researchers Zolfaghary Pour, S., Zhang, H., Liu, P.W., and their team have introduced an innovative approach that synergistically combines inverse design algorithms with state-of-the-art 3D printing techniques to create a multiport microwave power splitter. This development not only enhances the performance and scalability of microwave components but also paves the way for more versatile and customizable electromagnetic devices in future communication systems.

Microwave power splitters are crucial components in radio frequency and microwave engineering, responsible for dividing input power into multiple output channels with precise control over the power distribution and phase characteristics. Traditional methods for designing these splitters often grapple with complex geometrical configurations and material constraints, leading to bulkier designs or inefficiencies that limit their integration into compact devices. Addressing these challenges, the research team employed inverse design principles – a computational technique where the desired electromagnetic response is specified upfront, and the optimal structural configuration is algorithmically derived.

The inverse design framework implemented in this study transcends conventional design boundaries by enabling the automated discovery of intricate structures that satisfy multiple performance criteria simultaneously. Unlike traditional forward design methods that rely heavily on iterative trial-and-error and expert intuition, inverse design leverages advanced optimization algorithms and electromagnetic solvers to explore vast design spaces efficiently. This approach accelerates the design cycle, reduces reliance on manual tuning, and opens up possibilities for non-intuitive geometries that might have been previously overlooked.

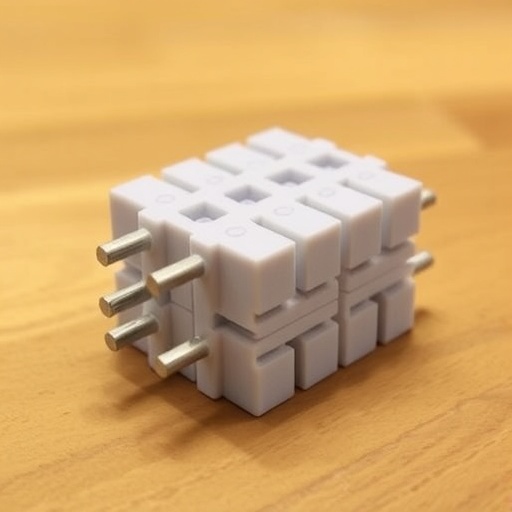

Central to this innovation is the integration of 3D printing technologies, which provide unparalleled freedom in fabricating complex three-dimensional geometries with high precision. By coupling the inverse design outputs directly with additive manufacturing processes, the researchers could realize physical devices that precisely correspond to the sophisticated designs generated computationally. This fusion eliminates typical fabrication obstacles associated with conventional subtractive manufacturing methods, such as multilayer assembly challenges and limitations in creating intricate internal features.

The multiport microwave power splitter developed in this work exhibits remarkable scalability, supporting multiple output channels with minimal insertion loss and high isolation among ports. The scalability aspect is particularly noteworthy, as it allows the splitter to be tailored for various applications ranging from antenna arrays in phased-array radar systems to complex routing networks in wireless communication infrastructures. The design’s adaptability ensures that it can meet increasingly stringent demands for bandwidth, power handling, and compactness.

One of the pivotal technical advancements in the study is the electromagnetic design framework that systematically incorporates material properties, manufacturing constraints, and electromagnetic performance targets into the inverse design process. This holistic integration ensures that the final designs are not only theoretically optimal but also practically viable for real-world deployment. The framework balances trade-offs between parameters such as return loss, isolation, phase imbalance, and power division ratios, achieving an optimal compromise tailored to specific application needs.

Moreover, through experimental validation, the fabricated power splitter demonstrated extraordinary agreement with simulated performance metrics, underscoring the accuracy and reliability of the design and fabrication pipeline. Measurement results highlighted low reflection coefficients across the operational bandwidth, uniform power distribution among output ports, and robust isolation levels, all achieved within a compact and lightweight device footprint. This alignment between simulation and experiment is a testament to the powerful synergy between inverse design algorithms and modern 3D printing capabilities.

The implications of this research extend beyond power splitters, potentially influencing a broad spectrum of microwave and millimeter-wave components where complex electromagnetic behavior must be harnessed within tight spatial constraints. Components such as filters, antennas, couplers, and multiplexers could benefit from similar design methodologies, enabling next-generation communication hardware that is both high-performing and highly customizable.

In addition to enhancing component functionality, the scalable design framework offers significant manufacturing advantages. Rapid prototyping through 3D printing accelerates the iteration cycle and enables customized devices tailored to specific operational scenarios without extensive retooling or cost overhead. This agility is increasingly important in modern communication environments characterized by rapid technology evolution and diverse deployment conditions.

Furthermore, the ability to produce multiport power splitters with complex internal architectures opens avenues for embedding additional functionalities within the same device, such as integrated filtering, impedance matching, or thermal management features. This multifunctional integration, facilitated by additive manufacturing, could lead to more compact and efficient subsystem designs, crucial for applications in aerospace, defense, and telecommunications.

From a theoretical standpoint, this work advances understanding of electromagnetic wave manipulation in three-dimensional structures optimized via inverse design. It showcases how computational electromagnetics, optimization theory, and advanced manufacturing can coalesce to tackle long-standing design challenges in ways previously unattainable. The research community and industry practitioners alike will find valuable insights in the methodologies and results presented, providing a blueprint for future innovations.

The significance of this study is further amplified by its prospective impact on emerging technologies such as 5G and beyond, Internet of Things (IoT) devices, and satellite communication systems. These applications demand high-performance components capable of operating across diverse frequency bands with stringent size, weight, and power constraints. The demonstrated framework aligns seamlessly with these requirements, offering a robust pathway to meet escalating technical and manufacturing demands.

Importantly, the versatility of the inverse design and fabrication paradigm means it can be adapted to incorporate new materials, including metamaterials or composites with tailored electromagnetic properties. This adaptability promises additional performance enhancements and novel functionalities, reinforcing the relevance of the framework in future research and commercial development.

In summary, the work by Zolfaghary Pour, Zhang, Liu, and colleagues exemplifies a transformative leap in microwave component engineering. By merging advanced inverse design techniques with the precision of 3D printing, they deliver a scalable electromagnetic design framework that redefines how multiport microwave power splitters can be conceived, fabricated, and deployed. This innovation not only meets current technological challenges but also opens fertile ground for ongoing exploration and application in the evolving landscape of electromagnetic device engineering.

As researchers continue to push the boundaries of what is possible through computational design and additive manufacturing, studies like this herald a new era of smart, customized, and highly efficient microwave systems that will underpin the next generation of global communication networks and beyond. The ripple effects of this breakthrough extend through both fundamental science and applied engineering, promising a future where electromagnetic devices are engineered with unprecedented precision and efficacy.

Subject of Research: Inverse design and 3D printing for scalable electromagnetic microwave power splitters

Article Title: Inverse design and 3D printing of a multiport microwave power splitter: a scalable electromagnetic design framework.

Article References:

Zolfaghary Pour, S., Zhang, H., Liu, P.W. et al. Inverse design and 3D printing of a multiport microwave power splitter: a scalable electromagnetic design framework.

Commun Eng (2026). https://doi.org/10.1038/s44172-026-00601-y

Image Credits: AI Generated

Tags: 3D printing techniques for electronicsadvanced communication technology componentschallenges in microwave component designcompact microwave engineering solutionsefficient radio frequency deviceselectromagnetic device customizationfuture trends in microwave engineeringinnovative fabrication methods for splittersinverse design algorithms for microwave componentsmultiport power splitter applicationspower distribution in microwave systemsscalable microwave power splitter design