With governments and environmental organizations pushing industries to reduce their greenhouse gas emissions, biopharmaceutical companies around the world are finding ways to make their business more sustainable. They have signed on to various initiatives, started their own programs, and joined committees, all in the name of reaching the United Nation’s Sustainable Development goal of “net-zero” by 2050.

As an energy- and resource-intensive industry, biopharma has a significant carbon footprint. “In the development of critical therapeutics, the stakes are particularly high, as these processes can … generate significant waste if not thoughtfully managed,” says Dai Ngo, Director of Product Management at Thermo Fisher Scientific.

Many companies have found that their efforts have not only lowered costs, but are essential for being competitive in the market, as pharmaceutical companies have higher expectations than ever when it comes to their partners’ Environmental, Social, and Governance (ESG) principles.

“They’re asking us to participate or prove what we’re doing and show that we’re putting systems in place,” says Elizabeth Hickman, CEO of AustinPx. “Our willingness to do that has helped strengthen our partnerships with our clients… and the methods in which we go about doing development, by thinking sustainably early on, will impact their long-term footprint.”

Developing green chemistry solutions

As key players in the pharmaceutical supply line, CDMOs have a big role to play in creating a more environmentally sustainable industry—including the smaller CDMOs, like AustinPx.

Working in oral drug product manufacturing, they have focused on replacing current amorphous solid dispersion (ASD) technologies that rely on toxic solvents to improve the bioavailability of poorly soluble drugs. With newer drug molecules having higher melting points and lower solubility, more solvents are now required in traditional spray drying techniques, resulting in more toxic waste. Instead, AustinPx has developed and built a novel method that is solvent-free, called KinetiSol™ Technology, which uses friction and shear energies created by high-speed mixing to solubilize drugs and polymers into ASDs.

In addition to eliminating the need for solvents, KinetiSol has a smaller operational footprint and faster processing times than traditional ASD technologies. Hickman believes that green chemistry solutions like these will have the biggest impact in the industry’s move toward sustainability, particularly for drug product manufacturing.

MilliporeSigma is also using green chemistry principles by developing safer and degradable chemicals. They have developed their own biodegradable detergent for virus inactivation, which is less toxic than the long-used Triton™ X-100 detergent that has been restricted in the European Union due to its toxicity.

“Our Deviron® detergents do not have the same structural characteristics as Triton X-100,” says Sebastian Arana, head of process solutions. While Triton X-100 degrades into products that are endocrine disruptors in aquatic and other environments, Deviron detergents have lower aquatic toxicity under the United Nations’ Globally Harmonized System (GHS) and meet the OECD Guideline 301B test for “readily biodegradable”. In addition, they have excellent viral inactivation performance and are easily removed during processing.

The global CDMO SK pharmteco is also using green chemistry principles to reduce solvent usage, particularly for their Active Pharmaceutical Ingredient (API) production. One way they have done this is by using Simulated Moving Bed (SMB) chromatography. As opposed to batch chromatography, SMB operates continuously. In one API project, using SMB, they were able to recycle 99.6% of the solvent, which minimized both waste generation and production costs. They were able to reduce their weekly solvent usage from 800,000 liters to just 3,200 liters, while achieving a 99.3% chiral purity and a Process Mass Intensity (PMI) of 1.9, versus a PMI of 30 with the traditional method.

Investing in renewable energy

As a part of the SK Group, SK pharmteco shares its parent company’s ESG-centric philosophy. The global CDMO is working towards achieving the highest standards in sustainable laboratory practices through the adoption of the My Green Lab initiative by 2030. They have several programs underway to meet these goals, which have already helped them achieve a 35% reduction in greenhouse gas emissions.

For instance, they are implementing Power Purchase Agreements (PPAs) for renewable electricity. “We source 100% renewables in our Ireland facility, which is a small molecule facility and massively energy-intensive,” says Darryl Ratty, the executive director of global ESG at SK pharmteco. Overall, 50% of the company’s electricity usage comes from renewable sources. They also have an ongoing energy efficiency program where they identify areas needing improvement.

Overall, Ratty believes that collaboration is essential for achieving sustainability within the pharmaceutical industry, both within the company and across the biopharma industry. At Thermo Fisher Scientific, they have a similar philosophy. “We’re committed to working across the ecosystem with our customers, suppliers, and partners to drive measurable progress and reduce the environmental footprint of our industry,” says Ngo.

“By building sustainability into the foundation of product development, we can help our customers meet their environmental goals without compromising performance or reliability,” she says.

Improving operations and products

Thermo Fisher is tackling sustainability from all sides. On the operational front, they currently have 27 certified zero-waste manufacturing and distribution sites, which use natural resources for operations and low-emission disposal methods, while the company-wide non-hazardous recycling rate is 53%. They also offer recycling programs to their customers, which have helped them “divert more than 400,000 pounds of plastic waste from landfills and incinerators,” says Ngo.

In addition to operational efficiency, they are focusing on building sustainability into their products through their Greener by Design product development program. “Products in this portfolio are evaluated using rigorous criteria such as water and energy efficiency, use of sustainable materials, reduced packaging, and end-of-life recyclability,” explains Ngo.

One such product is the DynaDrive Single-Use Bioreactor (S.U.B.). As a single-use technology, it doesn’t need to be cleaned or sterilized, which reduces water and chemical use as well as downtime. It also generates 27% less waste due to its packaging design and can reduce production costs by 25% compared to stainless steel bioreactors. Another example is their Biobased BioProcess Containers (BPCs), which are built on the same platforms as their Aegis™ and CX™ films, making it easy for customers to choose a sustainable alternative. “By switching to our biobased films, customers can eliminate carbon emissions equivalent to the impact of planting nearly 250,000 trees each year,” says Ngo.

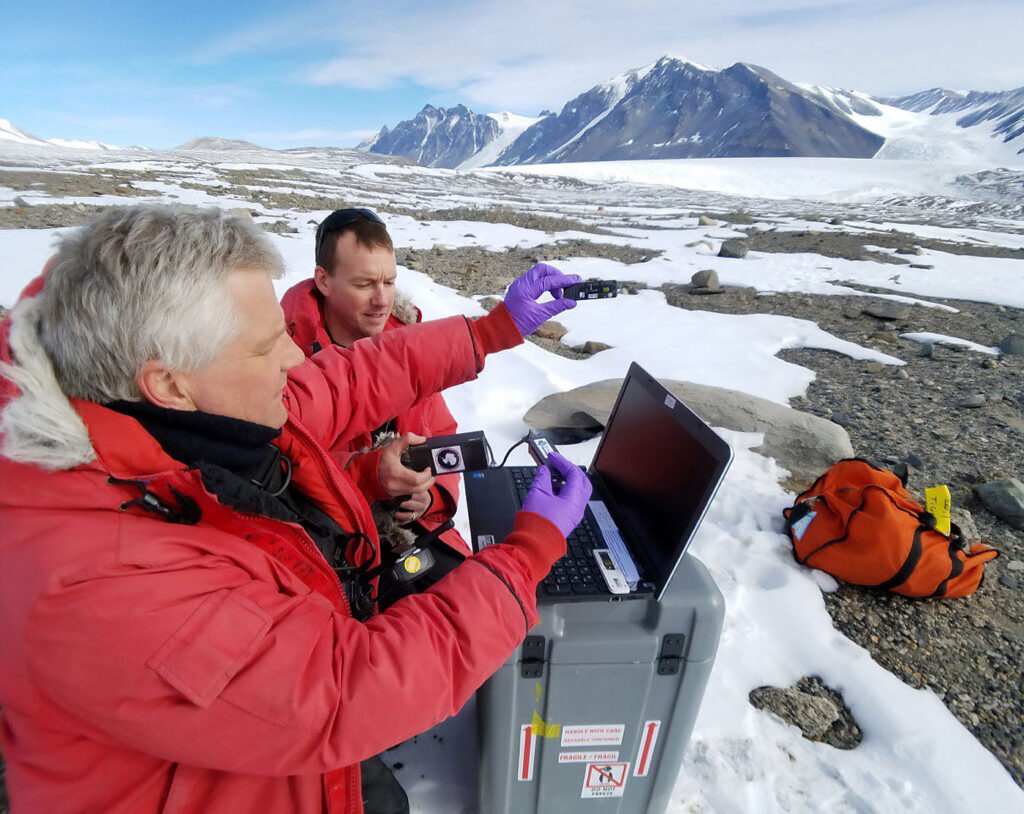

Oxford Nanopore Technologies is also reducing its direct greenhouse gas emissions through product recycling and waste reduction. For instance, through their Flow Cell Recycling Program, they are able to directly reuse their products, including PromethION and MinION Flow Cells. Last year, they saw a 63% increase in the tons of used products returned to them, and flow cell returns also improved from 32% in 2023 to 68% in 2024.

“We’ve also transitioned extensively to recyclable materials in our packaging, using Woolcool® insulation, Credo Boxes, and ensuring all our new packaging has high recycled content. It’s a very tangible way we’re reducing our environmental footprint,” says Tim Cowper, COO. “The MinION Mk1D device was our first product designed from the start to have entirely recyclable packaging, and we have applied these learnings to other devices.”

These efforts have led to a 10% cut in the company’s carbon intensity last year, but they have recognized that indirect emissions are where they can achieve significant further reductions and are working closely with their suppliers to do so.

Addressing the supply chain

As with the rest of the healthcare sector, most of the emissions from the biopharma industry come indirectly from the supply chain (Scope 3) rather than produced by (Scope 1) or in support of (Scope 2) company facilities. According to the scientist-led non-profit My Green Lab’s 2023 report, Scope 3 emissions in biotech and pharma are 4.6 times the amount of Scope 1 and 2 combined, with the vast majority coming from purchased goods and services. However, addressing emissions somewhat out of one’s control is not as straightforward as addressing emissions produced in-house.

For instance, at MilliporeSigma, they’re reducing the amount of plastic waste by redesigning products and lowering their carbon footprint by investing in energy-efficient upgrades to their facilities and Virtual PPAs. As a result, compared their 2020 baseline, “our Scope 1 emissions are down 36%, our Scope 2 emissions are down 56%,” says Arana. However, their Scope 3 emissions have only been reduced 1.5%. To address this, they recently launched Supplier Sustainability Toolkits to empower and upskill their suppliers in terms of sustainability.

At Oxford Nanopore Technologies, 57% of their total purchasing budget was dedicated to suppliers who have undergone ESG risk assessments in 2024. They have also provided specialized training to their suppliers on topics like energy audits, understanding their carbon footprints, and the Environmental Management Systems (EMS) framework, ISO14001. “We also plan to collaborate across industry sectors to scale these improvements further,” says Cowper. “We are still at the beginning of a long journey in addressing Scope 3 emissions, but we’re excited about the challenge and possibilities.”

Reassessing and strategizing

At Verdot, they have been monitoring their carbon footprint for 15 years. As a small bioprocessing technology company, Verdot’s Scope 1 and 2 emissions were already low compared to the rest of the industry. Nevertheless, they are advancing eco-design and material optimization for their equipment, and are defining their decarbonization strategy. This strategy includes providing the total carbon footprint of each of their products and making all chromatography columns and stainless-steel skids carbon neutral through carbon offsets.

However, like the rest of the industry, “Our highest emissions come from purchased goods, like raw materials and manufacturing processes,” says Emilie Bignon, the company’s health, safety, sustainability, and environmental manager. “We’re working on a responsible purchasing strategy to reduce this impact.”

In September, they are launching a more advanced carbon footprint assessment with more refined evaluation methods to identify where their supply chain needs improvement. According to Bignon, their clients’ demands for sustainable practices have created “a virtuous circle that pushes us all to improve. It drives our CSR (Corporate Social Responsibility) commitments, shapes our future priorities, and pushes us to communicate transparently and make concrete progress.”

“Sustainability is a natural extension of our engineering mindset and commitment to innovation,” says Bignon. “We believe good engineering should deliver efficient, long-lasting solutions that minimize resource use and environmental impact.”