In an age marked by rapid technological advancements and ever-evolving consumer electronics, the issue of electronic waste, or e-waste, has become a pressing concern for both the environment and society. With the proliferation of devices such as cellphones, laptops, tablets, and a myriad of home appliances, e-waste has surged dramatically. The latest findings from a report released by the United Nations highlight that the global e-waste tally has nearly doubled over the last 12 years, skyrocketing from 34 billion kilograms to an astonishing 62 billion kilograms. To put that into perspective, that weight is equivalent to 1.55 million fully loaded shipping trucks. The projections are equally alarming, as e-waste is expected to reach a staggering 82 billion kilograms by the year 2030. An unsettling 20 percent of this mass, translating to a mere 13.8 billion kilograms, is anticipated to be recycled—an amount that remains static at best, indicating that our efforts in recycling are failing to keep pace with the growing tide of discarded electronics.

Amidst this overwhelming challenge lies a glimmer of hope found in groundbreaking research conducted by a collaborative team from Virginia Tech. Their innovative study, soon to be published in the prestigious journal Advanced Materials, has unveiled a solution that could revolutionize the lifecycle of electronic devices. By devising a class of recyclable materials superior to current technologies, these researchers propose a method that may not only help in cutting down the amount of useless e-waste but also pave the way for the re-use of circuit materials in a sustainable manner. Their work brings together the disciplines of mechanical engineering and chemistry, emphasizing the importance of interdisciplinary approaches in solving complex issues such as e-waste management.

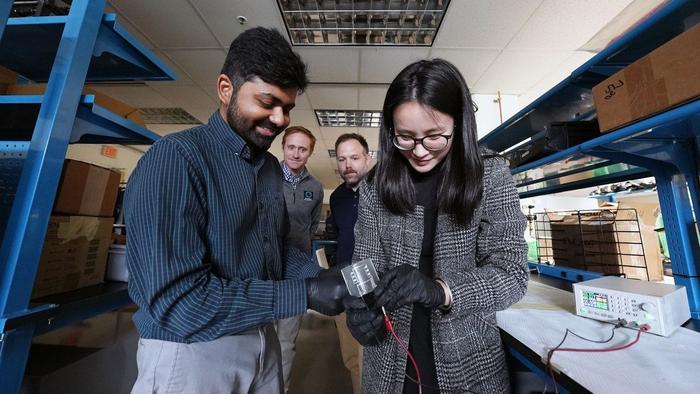

The research, spearheaded by Michael Bartlett, an associate professor of mechanical engineering, alongside Josh Worch, an assistant professor of chemistry, features a team of dedicated postdoctoral and graduate students. These innovators have developed a new kind of circuit material that stands out for its recyclability, electrical conductivity, and resilience. Uniting the traditional qualities expected of circuit boards, such as strength and durability, with novel features like self-healing and reconfigurability after damage, the material ensures a long-lasting product lifecycle while aligning with sustainability goals.

.adsslot_WAHZTSQUD0{ width:728px !important; height:90px !important; }

@media (max-width:1199px) { .adsslot_WAHZTSQUD0{ width:468px !important; height:60px !important; } }

@media (max-width:767px) { .adsslot_WAHZTSQUD0{ width:320px !important; height:50px !important; } }

ADVERTISEMENT

The material at the heart of this research is a vitrimer—an advanced polymer that allows for reshaping and recycling. This dynamic combination is integrated with droplets of liquid metal, a unique solution that mirrors the functionality of rigid metals found in conventional circuits. It marks a significant departure from existing recyclable and flexible electronic technologies by addressing an essential requirement: the need for materials that can perform reliably under varied conditions and challenges.

One of the significant advancements of this new circuit material is its resilience under mechanical deformation or damage. Traditional circuit boards often consist of thermoset materials that prove notoriously hard to recycle. Worch points out that the innovative dynamic composite can withstand damage and be repaired simply through heat application—a process that does not compromise its electrical performance. This critical distinction sets their work apart from existing technologies, signifying a step forward in the field of material science as it pertains to electronic components.

As the world wrestles with the escalating volume of e-waste, the research team’s findings suggest that the principles behind their circuit material could lead to more efficient recycling processes. Conventional circuit board recycling is typically marked by numerous energy-intensive deconstruction steps that mine large amounts of waste. Furthermore, the current methods result in the loss of billions of dollars worth of valuable metal components, which are essential not only for the economy but also for the sustainable reuse of materials.

In contrast, the recycling method proposed by the researchers is multifaceted and uncomplicated. The vitrimer circuit boards can be dismantled at the end of their life cycle by employing alkaline hydrolysis, showcasing an ability to reclaim key components such as liquid metal and light-emitting diodes (LEDs). This process is crucial for maintaining the integrity of resources and innovations within the electronic sector, pushing the agenda for sustainable development.

Ultimately, while it remains uncertain whether we can significantly reduce the quantity of electronics thrown away by consumers worldwide, this pioneering work by Virginia Tech marks a decisive stride toward addressing the challenge of e-waste. The quest for a sustainable future is rife with obstacles, but with research like this, one can envision a reality in which electronic devices serve not only their primary functions but also contribute positively to the environment.

Promoting the closed-loop process where all components of the conductive composites can be reused presents an ambitious yet achievable goal for future inquiries. It underlines the urgent need for a more integrated, thoughtful approach to the manufacturing and lifecycle management of electronic products. As technology continues to evolve rapidly, the importance of innovation in material science cannot be overstated.

Supported by various institutions within Virginia Tech, including the Institute for Critical Technology and Applied Science, along with funding through the National Science Foundation, this research exemplifies the commitment to deepening our understanding of adaptable materials. As the publication date draws near, anticipation builds within the academic community and the tech industry alike for the insights such studies will yield in combating the global e-waste epidemic.

Strongly embodied in their findings is the belief that moving towards technology that minimizes waste can indeed foster a more sustainable future. By encouraging collaborative efforts across scientific disciplines and fostering innovations that are environmentally friendly, we have the potential to reshape not only how we use technology but also how we respect and interact with our planet.

Subject of Research: Recyclable materials for electronics

Article Title: Liquid Metal-Vitrimer Conductive Composite for Recyclable and Resilient Electronics

News Publication Date: 1-Jun-2025

Web References: Advanced Materials DOI

References: 2024 United Nations e-waste report

Image Credits: Photo by Alex Parrish for Virginia Tech

Keywords

Tags: advanced materials in technologye-waste managementelectronic waste solutionsenvironmental impact of electronicsfuture of electronicsinnovative electronics researchrecycling challengesreducing electronic wasteself-healing technologysustainable consumer electronicssustainable electronicsVirginia Tech research