Reusing buffers in downstream operations would help biopharmaceutical manufacturers significantly reduce water consumption, making production more sustainable and cost efficient according to new analysis.

Current biopharmaceutical production methods rely on buffers. Lots of buffers. In upstream processes, water-based buffers control pH, optimize growth conditions and safeguard the protein during primary recovery.

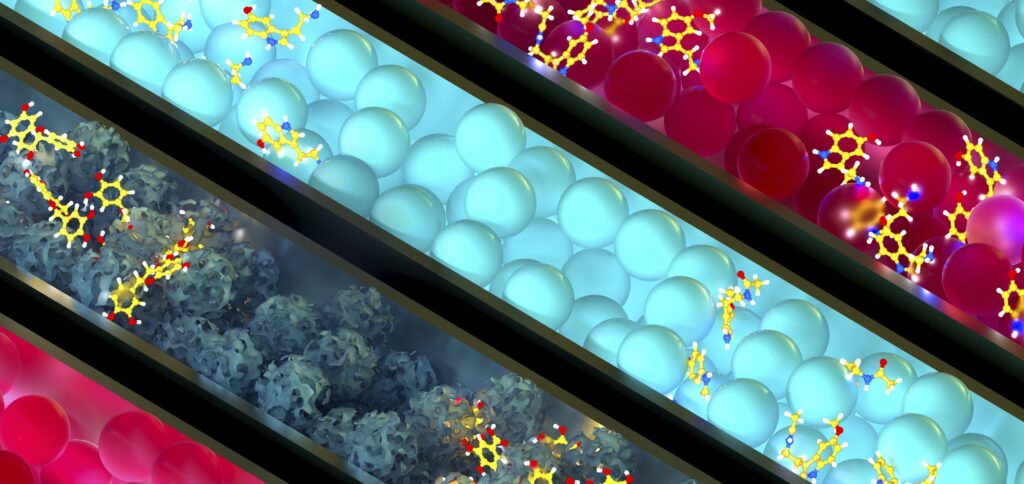

Likewise, in downstream operations, they maintain the desired purification conditions for chromatography. They also ensure the protein product retains its biological activity during formulation.

On average, it takes 65 liters of water to make the buffers needed to produce just one gram of product according to researchers at the University of Lund in Sweden, who say this level of water use is unsustainable, both environmentally and economically.

“Downstream processing costs are estimated to account for 70–90 percent of the total manufacturing expenses. Furthermore, water amounts to ∼95 percent of the components used in the downstream process. The production of biopharmaceuticals is thus costly and is a water- and chemical-intensive process.

“Given the global commitment to the goals for sustainable development and the anticipated growth of the biopharmaceutical market, the consumption of large buffer volumes is expected to become problematic,” they write.

Recycling

To address this, industry should consider using buffers more than once according to the authors, who point out that solvents used in biopharmaceutical manufacturing are routinely recycled.

“In pharmaceutical manufacturing processes based on organic solvents, the recycling of solvents through re-distillation is an established practice. In water-based biopharmaceutical downstream processing, buffer recycling has been discussed and there are practical examples where recycling occurs, for example in simulated moving bed and closed-loop recycling chromatography.

“However, buffer recycling is an intrinsic part of these unit operations and is performed to achieve the required purity, not primarily for reducing buffer consumption.”

To examine the impact of recycling on water consumption, the Lund University team developed a protocol that allowed them to reuse equilibration buffer during the chromatography steps in model monoclonal antibody (mAb) production processes.

And the results were encouraging.

“We could reduce the equilibration buffer consumption by 48 percent in the batch-to-batch process, and by 45% in the three-column PCC process. This corresponds to 11–12 percent of the total buffer consumption during the Protein A protocol,” they write.

In addition, the results suggest that, with appropriate control measures and constraints in place, buffer reuse does not have a detrimental impact on the biological activity of the protein product.

“During the buffer recycling runs, we sampled the recovered buffer and purified antibody and performed analysis. The introduction of buffer recycling does not result in impurity accumulation or change in yield or product quality, which indicates the constraints chosen for buffer recycling were suitable,” the authors write.

They conclude, “Through buffer recycling, we can improve process economics, reduce the environmental footprint and promote sustainability in biomanufacturing by using less water and chemicals, and by simultaneously reducing waste streams.”